PaperFlex1080 Backlight Osram LED module (2900 lm/sqm)

Professional Paper-Flex Osram LED Strips with 35 cm width and 3300 lm per square meter. You can light up 9 square meters at once!

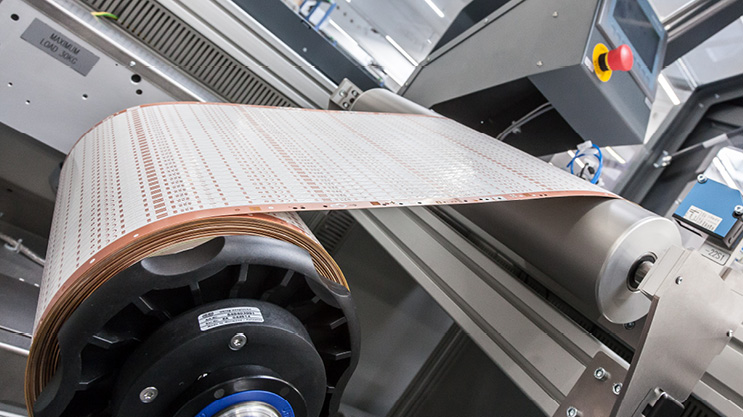

A world premier, the new Paper-Flex is made possible by using the innovative production method of printed electronics, at our new state of the art Flex production line in Germany.

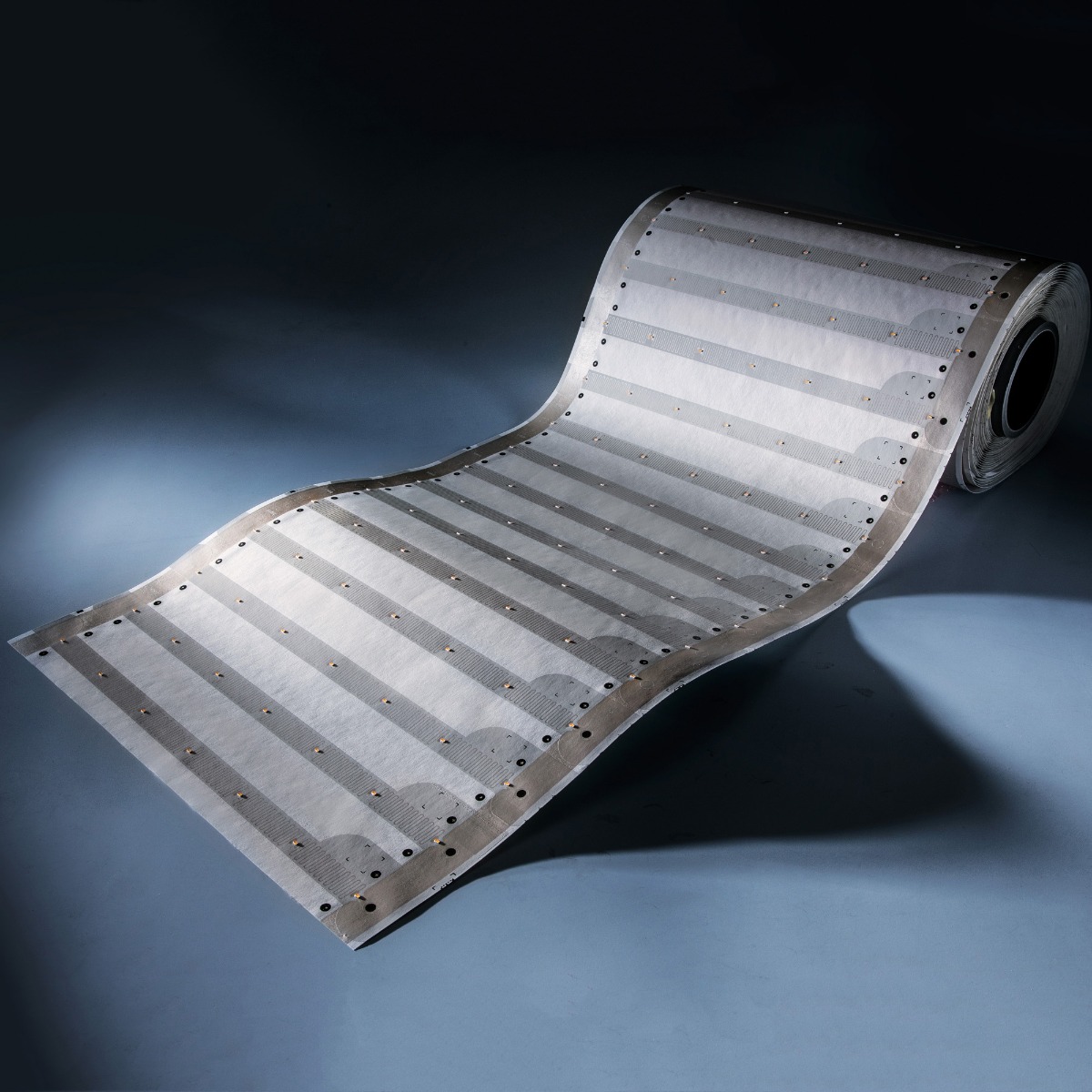

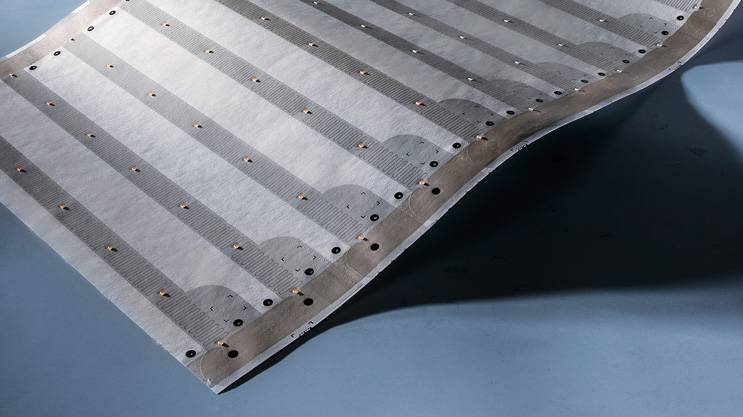

Paper-Flex is a reel of luminous, flexible paper, with an amazing lenght of 24.85 m and surface area of 8.69 square meters, that will light up at once from a 24VDC transformer. It is currently the only LED module that uses paper as a base material, with many new possible applications: from classic luminaire production, to the furniture industry, packaging and advertising industry and countless more.

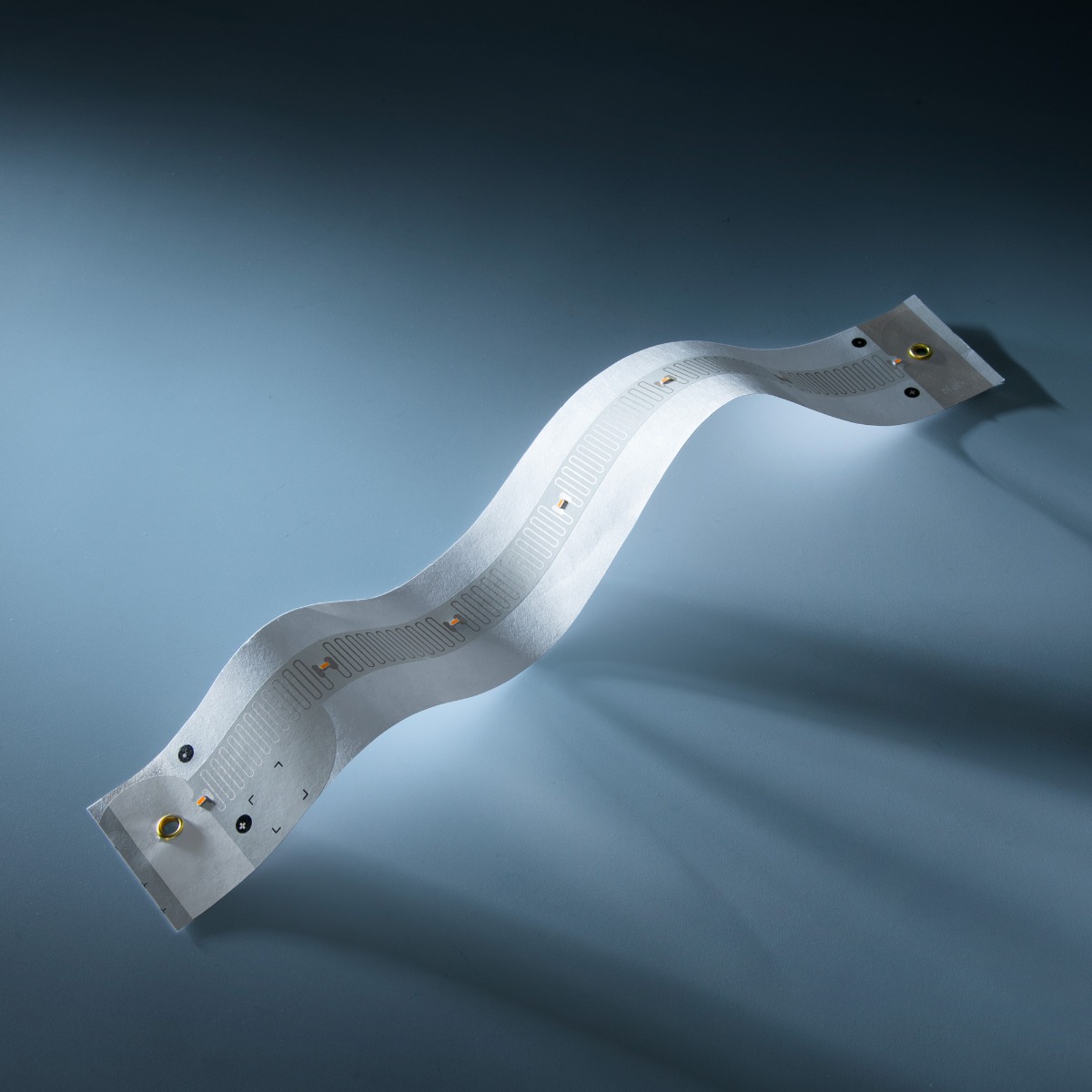

Huge surfaces can be back-lit with this wallpaper like LED module, faster and easier as ever before. Lighting fixtures with unique designs or shapes can be created with the Paper-Flex installed as illuminated ribbons, tubes, waves, domes or hills, just as regular paper.

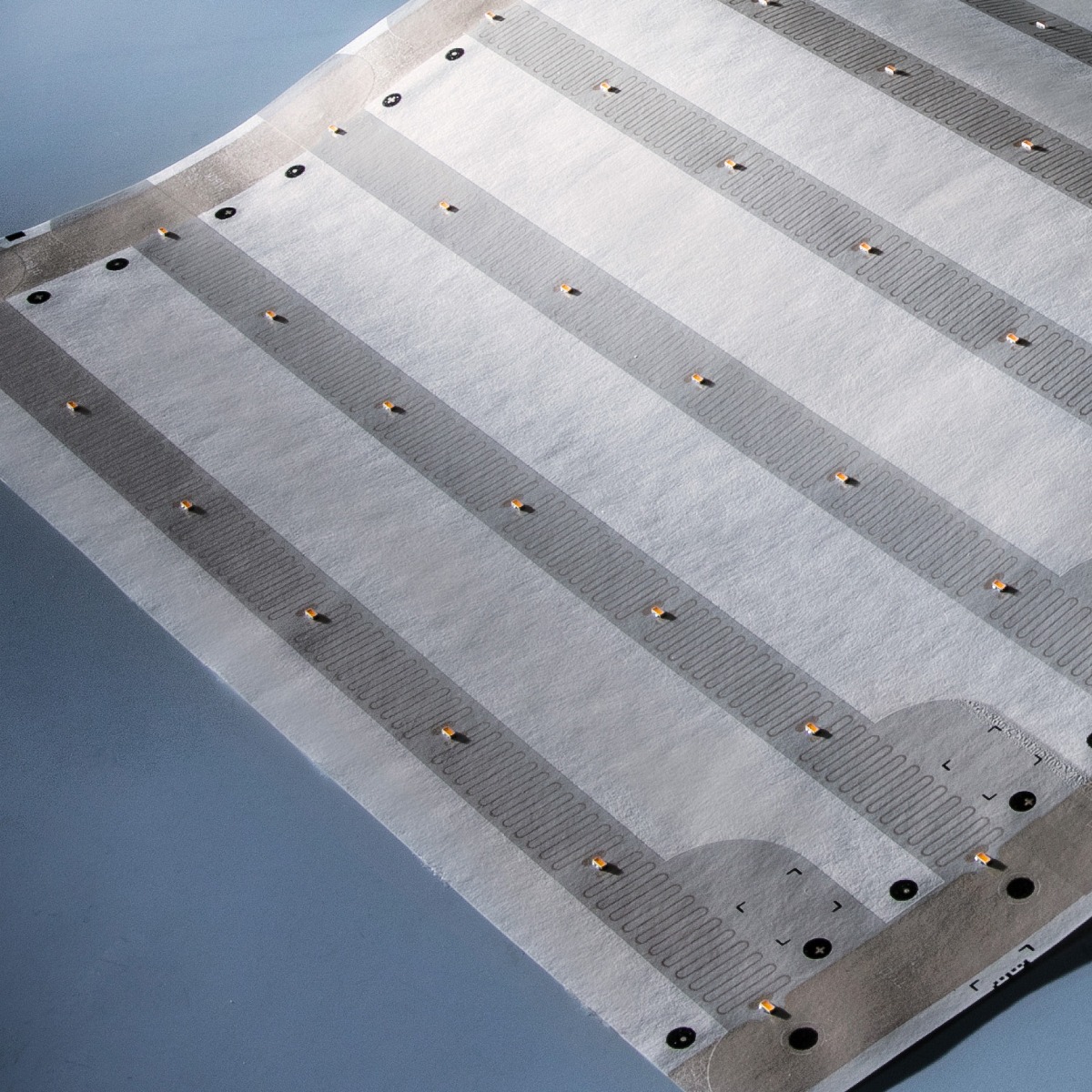

Paper-Flex is 35 cm wide, with lines of LEDs at every 5 cm. The line is the smallest unit of Paper-Flex, with 7 Osram Duris LEDs. This row of LEDs has a luminous flux of 55 lm for color temperature of 3000 K and CRI >80. However, on demand, other color temperatures and CRI levels are available.

The paper substrate is ultra-flat (approx. 0.8 mm after assembly) and thus more than suitable for large-area applications where a low mounting height is required. The low power density and breath-ability of the paper ensure that no heathsinks are required and eliminate the danger of moisture accumulation.

Delivery information:

We will deliver Paper-Flex according to your order, in a continuous reel with the number of rows (pcs) in your purchase, up to a maximum number of 497 rows, total 24.85 m. So for example, if you order 100 pieces you will get a reel with 100 rows, 5 meters long and 35 cm wide. One piece (row) is 5 cm long and 35 cm wide, with 7 LEDs. The Paper Flex is also available to purchase as one full reel, 24.85m long, article code 35548.

Features of one reel of Paper-Flex LED paper strip-module (article number 35548)- PCB Base material: reel of paper 24.85m long, 35 cm wide

- Extremely light, flat and sustainable

- 3479 Osram Duris LEDs

- Luminous flux total: 27335 lm

- Total power consumption: 178.92 W

- Luminous flux for one meter: 1100 lm

- Power consumption: 7.2 W

- Luminous flux for one square meter: 3300 lm

- Power consumption: 21.6 W

- Luminous flux for one row: 55 lm

- Power consumption: 0.36 W

The Paper-Flex comes with a high degree of customizability. Depending on your wishes, you can choose from a wide variety of decorative surfaces. Whether with or without punching or diffusion layer - basically any combination is possible.

Even the combination of modules for double-sided lighting is conceivable. The option of additional sensors for measuring and controlling data, such as temperature or humidity, further expands the potential. This can generate great added value, especially in the packaging industry.

Applications of the Flexible Paper-Flex LED strip-module

- Wallpaper light

- Back-lighting of very large advertising spaces

- Illuminated stretched - ceilings

- Decorations and back lighting of furniture

- Exhibition lighting

- Luminaire production

- Large surface lighting with curved shapes

Paper-Flex Osram LED Strip

Paper-Flex LED strip documentation

Our new Flex production line in Germany will expand your possibilities

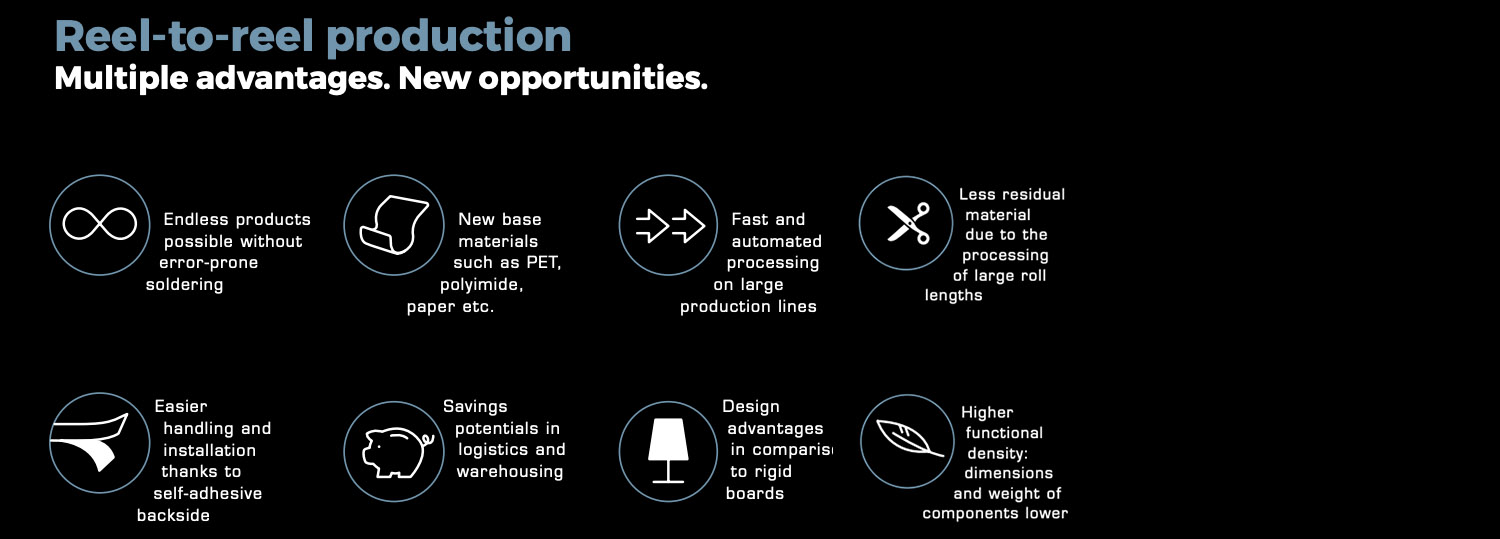

Our innovative manufacturing technology, with the patented process of plasma direct metallization, turns flexible substrates into electrical conductive and solderable circuit boards, even those that before have not been suitable for an assembly with electronic components.

Thus, the new materials we can use open up many new application possibilities in the lighting industry and beyond.

One such material is the solderable flexible paper as used in Paper-Flex, a cost effective PCB that is open to diffusion and therefore ideal for large-area applications such as wallpaper or advertising spaces.

PET can also serve as the base material for PCBs. This plastic is cheaper than polyimide, has very good strength, high resilience and low weight. Coated with a thin aluminum layer, which is made solderable by plasma metallization, the PET-FPCs can be equipped with components.

In addition, materials provided by our customers can be equipped with electronic components in-house after a feasibility test.

Our reel-to-reel production offers multiple advantages, from delivering many customs designs without the error of soldering to the use of new base materials that make new designs possible, with easier handling, installation and transportation.

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA