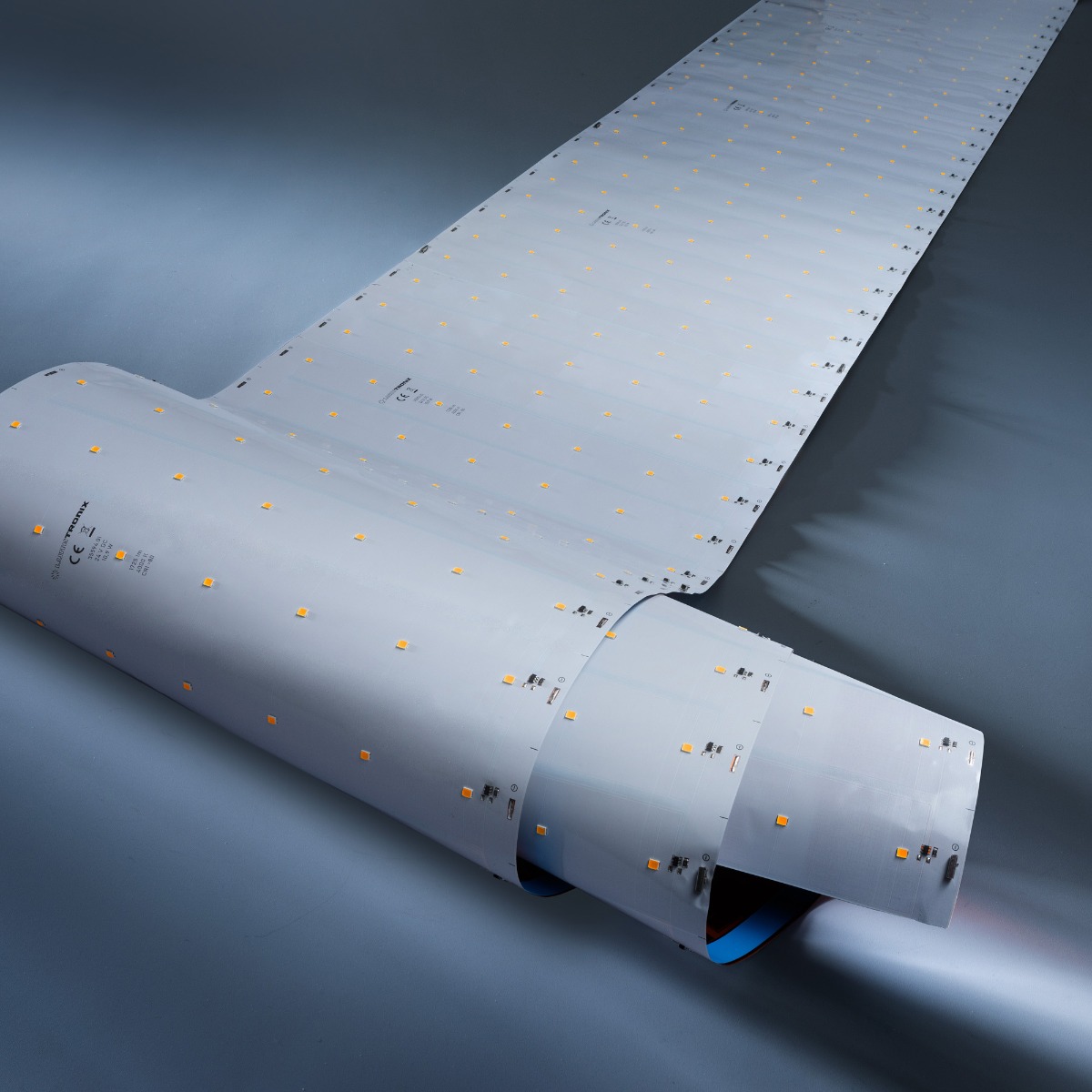

LumiFlex4080 Seoul LED strips 5.6m reel (5200-6200 lm/m)

Professional LumiFlex4080 Seoul LED Strips, up to 6200 lm per meter, in single or multi row versions

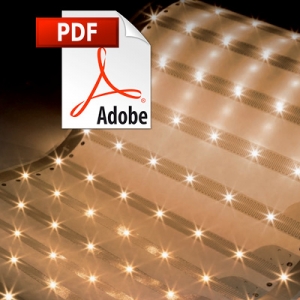

The new LumiFlex4080 LED strips are made possible by using the innovative production method of printed electronics, at our new state of the art Flex production line in Germany.

LumiFlex4080 LED strips push the limits of luminous performance to new heights, with 5300 lumens per meter from only a single row of LEDs.

With the LumiFlex4080 LED strip extremely bright linear fixtures can be built with minimum assembly work due to the Zhang-compatible dimensions and plug and play design, with connectors. The LumiFlex4080 is available in reel format, 5.6m long with 20 modules and can be cut at every 28 cm, which is the shortest possible length. Each module functions at a low voltage of 8.25V and respects the SELV standard.

LumiFlex-20-4080 LED sheet can bring intense light to wide surfaces with its wallpaper like design, with fast and easy installation. Very luminous lighting fixtures with unique designs or shapes can be created with this LumiFlex installed as illuminated ribbons, tubes, waves, domes or hills, just as regular paper. One reel ofLumiFlex-20-4080 is 5.6m long and can be separated into 28 cm long modules, each with connectors and 49 LEDs. You can power the full length of the reel at 24VDC, it will light up at once.

The cost of LumiFlex LED strip is quickly covered due to minimal energy consumption and nonexistent maintenance costs for years or even decades of operation. For the safety of the investment, the strips come with a warranty of 5 years.

Features of one LumiFlex4080 LED strip

- One reel with one row of 540 LEDs; 27 LEDs per module of 28 cm

- Seoul Semiconductor 3528 LEDs with 54000h lifetime at L70B50

- 5.6m length with 20 modules

- Luminous flux up to 5300 lm/m for 26W/m

- Zhaga-compatible

- Efficiency up to 197 lm/W

- Easy installation due to double-sided, thermally conductive adhesive tape

- Production in reel-to-reel process (R2R)

- Base material: PET

- Dimensions: 5600 x 20 x 2.8 mm

Features of one LumiFlex-20-4080 LED strip

- One reel with 7 rows and 980 LEDs in total; 49 LEDs per square module of 28 cm

- Seoul Semiconductor 3528 LEDs with 54000h lifetime at L70B50

- 5.6m length with 20 modules

- Luminous flux up to 6200 lm/m for 39W/m

- Zhaga-compatible

- Efficiency up to 160 lm/W

- Easy installation due to double-sided, thermally conductive adhesive tape

- Production in reel-to-reel process (R2R)

- Dimensions: 5600 x 280 x 2.8 mm

Applications of the LumiFlex LED strip

- Linear luminaires

- Cove lighting

- Illuminated stretched - ceilings

- Back lighting of furniture or other surfaces

- Exhibition lighting

- Luminaire production

- Large surface lighting with curved shapes

- Construction of light bodies or LED panels

LumiFlex4080 LED Strip

LumiFlex-20-4080 LED module

-

Constant Current LED Driver Mean Well LCM-40 IP20 350 > 1050 mA 230V to 2 > 100VDC DIMRating:0%€38.52Stock >10 pcs

Constant Current LED Driver Mean Well LCM-40 IP20 350 > 1050 mA 230V to 2 > 100VDC DIMRating:0%€38.52Stock >10 pcs -

Constant Voltage Power Supply Mean Well HLG-320H-24B IP67 230V to 24V 13.34A 320W DIMRating:0%€135.30Low Stock, only 10 pcs.

Constant Voltage Power Supply Mean Well HLG-320H-24B IP67 230V to 24V 13.34A 320W DIMRating:0%€135.30Low Stock, only 10 pcs.

Z-Flex LED strip documentation

Our new Flex production line in Germany will expand your possibilities

Our innovative manufacturing technology, with the patented process of plasma direct metallization, turns flexible substrates into electrical conductive and solderable circuit boards, even those that before have not been suitable for an assembly with electronic components.

Thus, the new materials we can use open up many new application possibilities in the lighting industry and beyond.

One such material is the solderable flexible PET as used in Z-Flex. This plastic is cheaper than polyimide, has very good strength, high resilience and low weight. Coated with a thin aluminum layer, which is made solderable by plasma metallization, the PET-FPCs can be equipped with components.

Another option is solderable flexible paper as used in Paper-Flex, a cost effective PCB that is open to diffusion and therefore ideal for large-area applications such as wallpaper or advertising spaces.

In addition, materials provided by our customers can be equipped with electronic components in-house after a feasibility test.

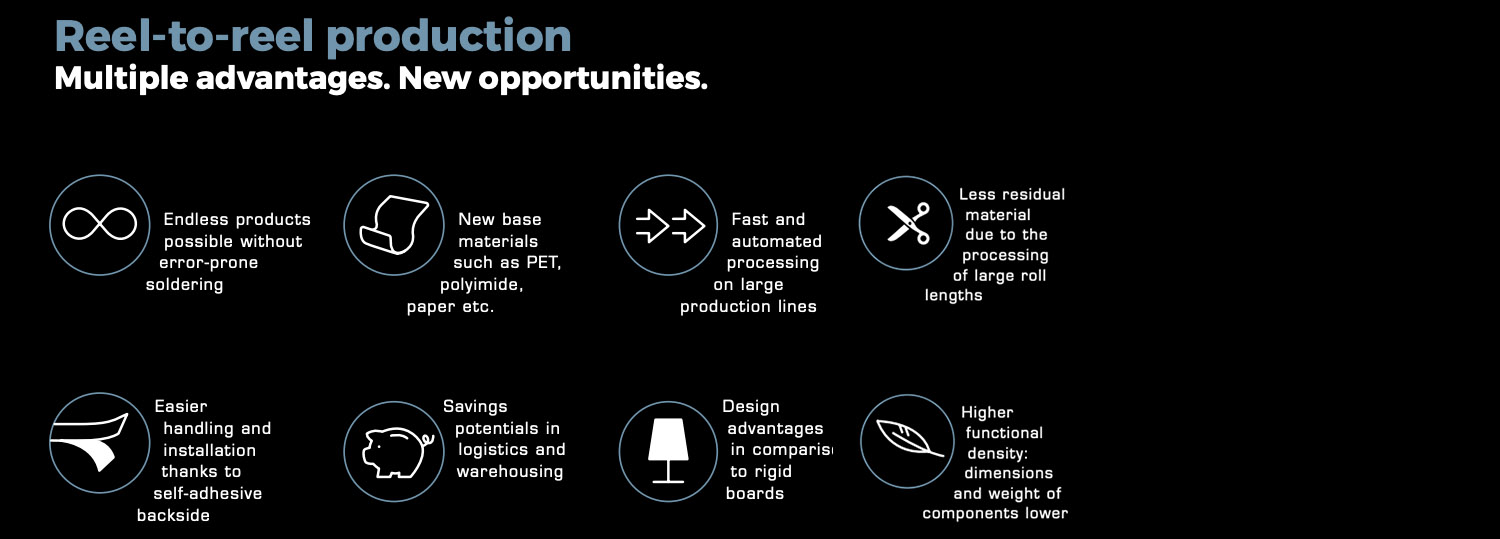

Our reel-to-reel production offers multiple advantages, from delivering many customs designs without the error of soldering to the use of new base materials that make new designs possible, with easier handling, installation and transportation.

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA