Nichia 280nm UVC LED Modules – Advanced Disinfection & Sterilization Solutions

Nichia High Output UVC 280nm LED Modules: Advanced Solutions for Disinfection and Curing

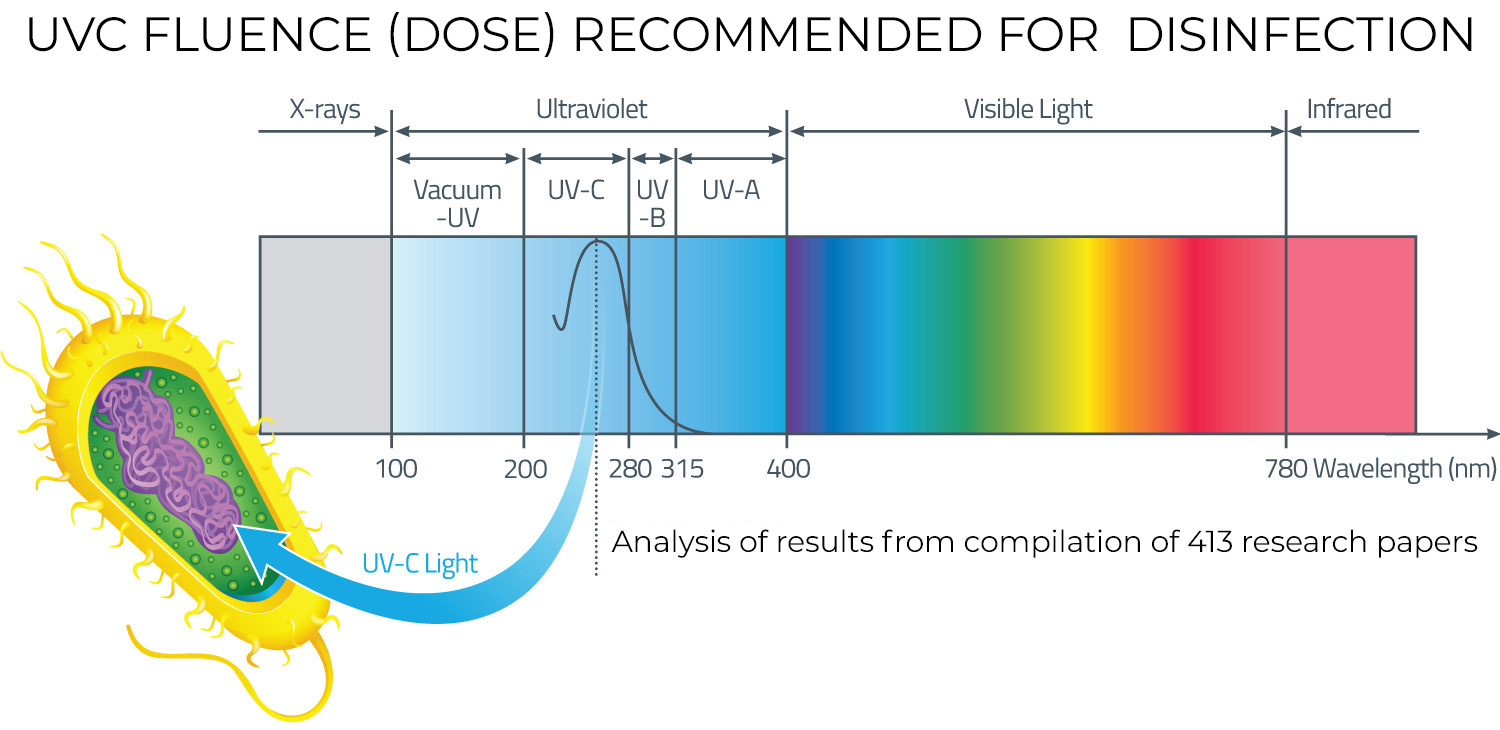

Disinfection and sterilization are critical processes, especially in medical, industrial, and public health applications. Traditional sterilization methods, such as chemical treatments and high temperatures, are effective but often come with limitations. UV-C radiation, particularly within the wavelength range of 280 to 100 nm, is highly effective in inactivating pathogens like viruses, bacteria, and other microorganisms within a very short time. The rapid advancement of LED technology has enabled the development of powerful UVC LEDs that offer high design flexibility and efficiency for sterilization purposes.

Nichia High Output 280nm UVC LEDs are specialized light-emitting diodes designed to emit ultraviolet light at a precise wavelength of 280 nanometers, known for its potent germicidal properties. These UVC LEDs are ideal for various disinfection and sterilization applications, including air purification, mold control, water treatment, and surface disinfection.

UVC LED modules offer many advantages over UV lamps and great design flexibility thanks to their compact design:

- Less electrical power required - perfect for battery-powered applications

- Robust against physical stress (e.g. vibration) - perfect for mobile use

- Environmentally friendly - no mercury; no ozone (>240nm)

- Unlimited switching cycles

- No warm-up phase, full optical power right from the start

- Pulsed operation possible for higher optical power; 100% dimmable

- Targeted use of different wavelengths (mixed assembly on one circuit board)

- Option of using lenses to focus the UV-C light in a targeted manner

- Safety system based on our Power Controller V2

- Less damage to exposed surfaces from UV-C light compared to other UV-C technologies with higher output

As a leading LED manufacturer, Nichia provides high-output UVC LEDs that deliver superior performance, reliability, and efficiency. Partnering with Nichia, we produce high-quality UV LED modules in Germany, combining our extensive experience in LED lighting with Nichia's advanced UV LED technology to ensure exceptional radiant power, energy efficiency, and longevity. Nichia's expertise in UV LED manufacturing, combined with our commitment to quality, results in modules that are not only powerful but also incredibly reliable, providing consistent performance across various applications. These modules are designed to meet the highest standards of durability and efficiency, making them an excellent choice for industries requiring robust and effective disinfection solutions.

Our UV LED modules can be customized to meet the specific needs of various industries, including luminaire manufacturers, medical technology companies, and other sectors that require precise and effective UV disinfection. This customization includes adjusting the number and arrangement of LEDs, incorporating lenses to focus the UV light, and integrating features such as dimming capabilities and different color temperature adjustments. By offering tailored solutions, we ensure that our UV LED modules can address the unique challenges and requirements of each application, providing a flexible and versatile solution for disinfection and curing. This adaptability, combined with the superior performance of Nichia's UVC LEDs, positions our modules as a top choice for businesses looking to enhance their disinfection capabilities with cutting-edge technology.

In our UVC modules, we use the latest generation Nichia UV LED series:

- NCSU434C (280nm): 3535 Glass Package, 3.5×3.5mm

- NCSU434B (280nm): 3535 Glass Package, 3.5×3.5mm

- NCSU334B (280nm): 6868 Glass Package, 6.8×6.8mm

- NC4U334BR (280nm): 6868 Glass Package, 6.8×6.8mm

Benefits of Nichia High Output UVC LEDs for Disinfection and Curing

-

Performance and Reliability: Nichia UVC LEDs ensure consistent performance and reliability. They provide stable ultraviolet light output, maintain spectral integrity, and operate efficiently without flickering or diminishing in intensity prematurely.

-

Enhanced Germicidal Efficacy: Nichia UVC LEDs deliver precise wavelengths that maximize germicidal efficacy, ensuring effective inactivation of microorganisms and providing thorough and reliable disinfection.

-

Longevity: High-quality Nichia UVC LEDs are constructed with superior materials that withstand continuous operation. This durability means fewer replacements and lower maintenance costs, enhancing the return on investment.

-

Safety: Top-quality UVC LEDs adhere to strict safety standards, ensuring that disinfection systems are safe to operate and install, reducing the risk of exposure to harmful ultraviolet radiation and potential hazards.

-

Environmental Impact: Nichia UVC LEDs are manufactured using environmentally friendly processes and materials. By opting for high-quality UVC LEDs, manufacturers contribute to sustainability efforts, reducing waste and minimizing the environmental footprint of their products.

Applications of Nichia High Output 280nm UVC LEDs

-

Air Disinfection: UVC LEDs can be integrated into HVAC systems and air purifiers to disinfect the air, eliminating airborne pathogens and reducing the risk of airborne diseases. This is particularly important in hospitals, offices, and public spaces where air quality is critical.

-

Mold Control: UVC LEDs are effective in preventing and controlling mold growth in damp and humid environments. They can be used in basements, bathrooms, and ventilation systems to maintain a mold-free environment, improving indoor air quality and health.

-

Water Disinfection: UVC LEDs provide a chemical-free method for disinfecting water, making them ideal for use in residential water purifiers, industrial water treatment plants, and municipal water systems. They ensure that water is safe for drinking and other uses by eliminating harmful microorganisms.

-

Surface Disinfection: UVC LEDs can be used to disinfect surfaces in healthcare settings, laboratories, and food processing facilities. They effectively eliminate pathogens on countertops, medical equipment, and other surfaces, ensuring a hygienic environment.

Case Study – Simulation for Surface Disinfection with four Violet UVC LED modules for 20 square meters

Irradiation with UVC LED systems is an effective approach to maintaining germ-free environments in heavily frequented rooms, complementing conventional sterilization methods. In a simulated scenario for surface sterilization in a doctor’s office, the dimensions were set at 4 m by 5 m, with a height of 2.5 m. Four linear high-performance "Violet" modules emitting at 280 nm were used, positioned above critical surfaces like an instrument table, treatment couch, desk, and cabinet.

Evaluating UVC Disinfection: Required Fluence for Optimal Pathogen Reduction

While numerous studies have demonstrated the effectiveness of UV light in disinfection and sterilization, the wide variance in results poses a challenge in determining definitive answers to these questions.

Our recommendations are based on an analysis of 413 research papers compiled in "Fluence (UVC Dose) Required for up to 99% disinfection from Viruses, Bacteria, Protozoa, and Algae." This compilation can be downloaded via the links below:

PDF: Fluence (UV Dose) Required to Achieve Incremental Log Inactivation of Bacteria, Protozoa, Viruses, and Algae

These studies provide data on the fluence required to achieve log reductions from 1 to 5 for various UVC sources.

The effectiveness of UV light in sterilization or disinfection depends on exposure, time, wavelength, and irradiance.

- Exposure or fluence (sometimes called dose) is measured in mJ/cm² (where 1 mJ/cm² = 10 J/m²).

- Exposure time is measured in seconds (s), minutes (m), or hours (h).

- Irradiance is the flux of radiant energy per unit area, indicating how much UV radiation power (measured in W = 1000 milliwatts (mW) = 1,000,000 microwatts (µW)) reaches the surface. It is measured in mW/cm² or W/m² (1 mW/cm² = 10 W/m²) and depends on the radiant power, distance, and dispersion of the radiation emitted by the lamp source.

Log Reduction Explained

"Log reduction" is a mathematical term indicating the relative number of live pathogens eliminated from a surface by disinfecting. For instance, a "5-log reduction" means lowering the number of microorganisms by 100,000-fold, meaning if a surface has 100,000 pathogenic microbes, a "5-log reduction" would reduce the number to one, equating to a 99.999% kill rate.

Common log reductions in UV light disinfection research range from 1 to 5:

- "1 log reduction" means the number of germs is 10 times smaller (10¹).

- "2 log reduction" means the number of germs is 100 times smaller (10²).

- "3 log reduction" means the number of germs is 1,000 times smaller (10³).

- "4 log reduction" means the number of germs is 10,000 times smaller (10⁴).

- "5 log reduction" means the number of germs is 100,000 times smaller (10⁵).

| Log Reduction | Kill rate of microorganisms |

| 1 | 90% |

| 2 | 99% |

| 3 | 99.9% |

| 4 | 99.99% |

| 5 | 99.999% |

Compilation of Results from 431 Disinfection Experiments with UVC Radiation

The PDF tables compile log reduction results from 431 experiments on the effects of UV disinfection on bacteria, protozoa, viruses, and algae. These studies, along with similar others, inform the science behind designing and deploying UV lamp systems for sterilization or disinfection.

For each pathogen, the fluence (dose) required to achieve the given log reduction is expressed in mJ/cm² when exposed to the UV radiation of the test lamp. The lamps used in the tests, detailed in each result, include UVC LEDs.

UVC LEDs

Tables 1-5 summarize published data on UV fluence-response for various microorganisms. The tables reflect the current state of knowledge but also highlight the variation in techniques and biological responses due to the lack of standardized protocols. Users are advised to exercise critical judgment when utilizing the data.

A fluence of 20 mJ/cm² or less was sufficient for a 90% kill rate (1 log reduction) in 81.90% of the 431 studies, whereas 8.82% required up to 30 mJ/cm², and 9.28% needed 30 to 50+ mJ/cm².

| Maximum Fluence (dose) for 90% kill rate (log 1 reduction) | Number of studies | % of total studies |

| 0.1-5 | 202 | 46.67% |

| 5-10 | 76 | 17.83% |

| 10-20 | 75 | 17.40% |

| 20-30 | 38 | 8.82% |

| 30-40 | 17 | 3.94% |

| 40-50 | 9 | 2.09% |

| >50 | 14 | 3.25% |

A fluence of 20 mJ/cm² can be achieved with an irradiance of 10 W/m² (1 mW/cm²) in 20 seconds, in 66 seconds at 3 W/m² (0.33 mW/cm²), and in 200 seconds at 1 W/m² (0.1 mW/cm² = 100 µW/cm²).

In 51% of the studies, a fluence of 6 mJ/cm² was enough for a 90% kill rate, requiring only 60 seconds at 1 W/m².

Viruses vs. Bacteria Resistance to UV

Research indicates that bacteria require less fluence for significant reduction, with 90% inactivation achievable with less than 12 mJ/cm² in 82% of studies, showing that disinfection from bacteria is more easily achieved with UV light—good news for hospitals dealing with drug-resistant strains.

Viruses, however, are more resistant, needing up to 20 mJ/cm² in 75% of studies and up to 80 mJ/cm² in 22%.

| Pathogen | Number of studies | Maximum Fluence (dose) for 90% kill rate (log 1 reduction) | % of total studies |

| Viruses | 149 | 20 mJ/cm2 | 75% |

| Bacteria | 112 | 5 mJ/cm2 | 82% |

90% Disinfection Rate as a Design Goal

When designing a UV disinfection system, consider the fluence increase needed for more than 90% microorganism reduction, especially for a target value of 99.9% (3 log). The compilation shows that achieving 99.9% disinfection instead of 90% requires over 200% more fluence on average, while a 99% kill rate is possible with a 95% increase.

Practically, a 95-200% increase in exposure time or irradiance per m², and consequently installation and operational costs, only improves the result by up to 10%. Therefore, a 99.9% disinfection rate, though ideal, is impractical for widespread use in fighting pandemics.

If 99.9% disinfection is unfeasible, the goal should be 90%, especially when augmented with other measures like cleaning or personal hygiene. This goal allows for equipping three times more healthcare facilities with continuous disinfection systems within a fixed budget.

As our analysis shows, the recommended UVC disinfection system should achieve a fluence of 20 mJ/cm² within the planned operating time.

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips ITA

Lumistrips ITA