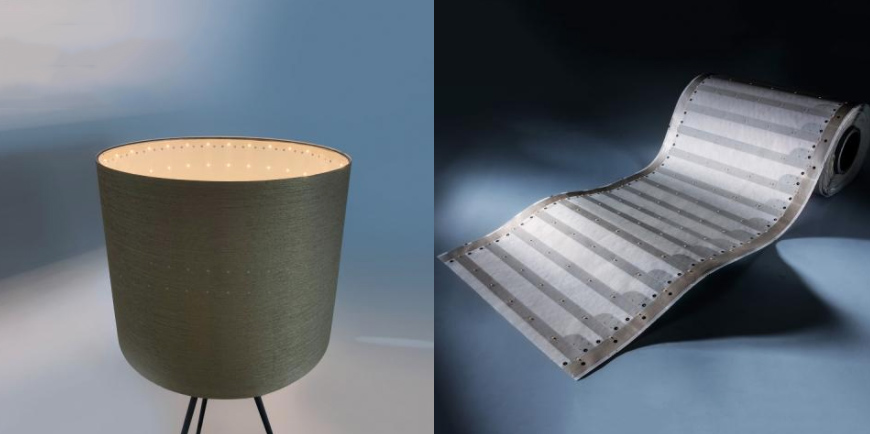

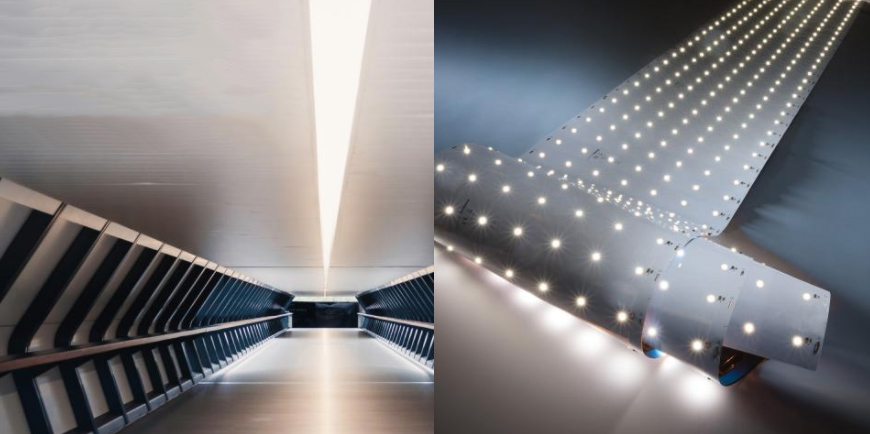

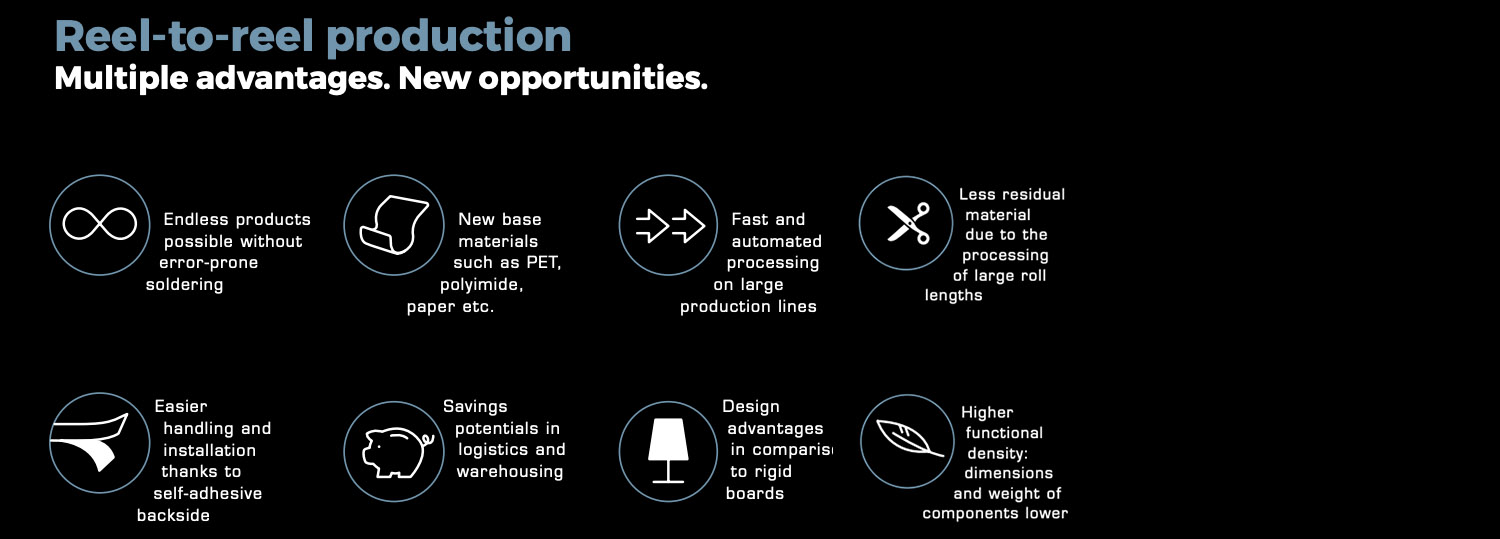

Our new Flex production line in Germany will expand your possibilities, with new materials used in reel-to-reel manufacturing

With this patented process, the new materials we use as base for our LED strips and modules will open up many new application possibilities in the lighting industry and beyond.

At the Lumistrips production facility in Germany we value the highest quality.

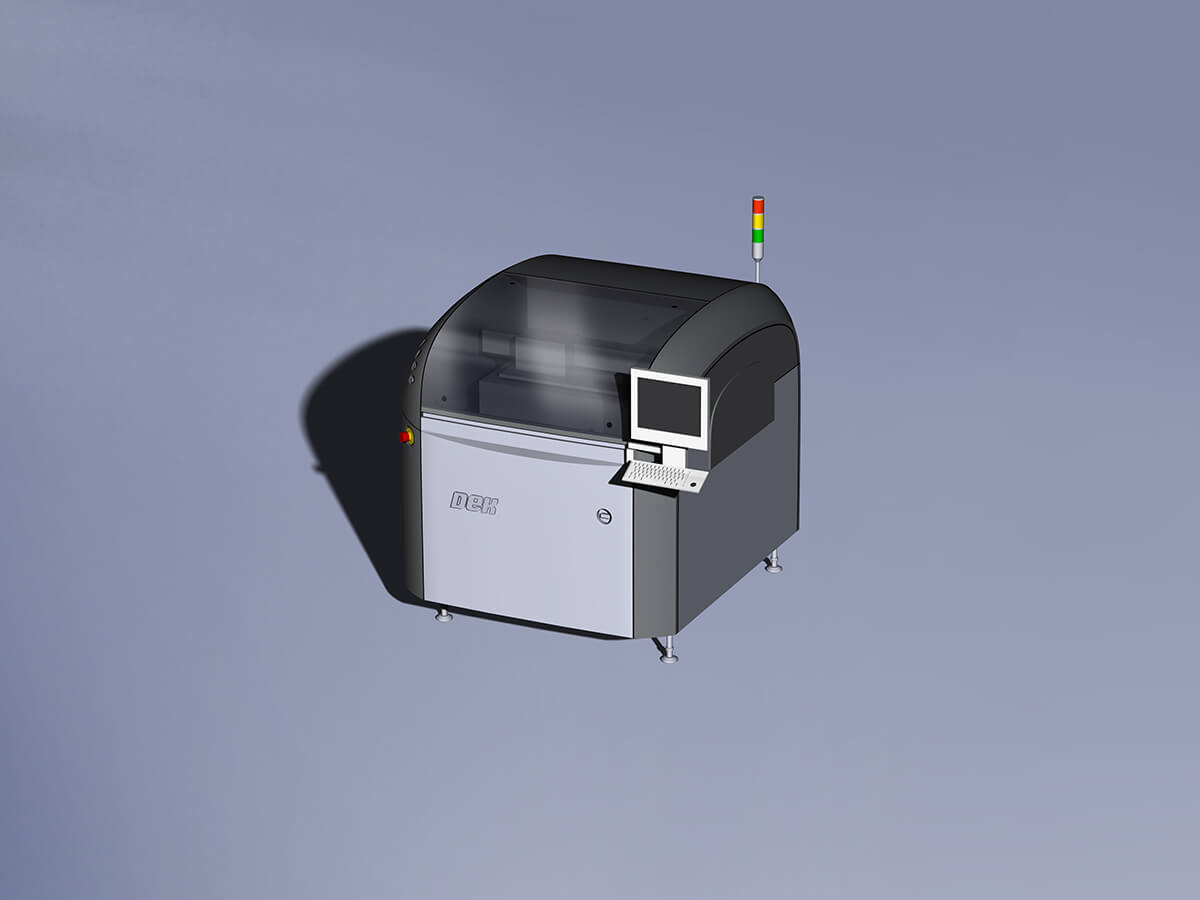

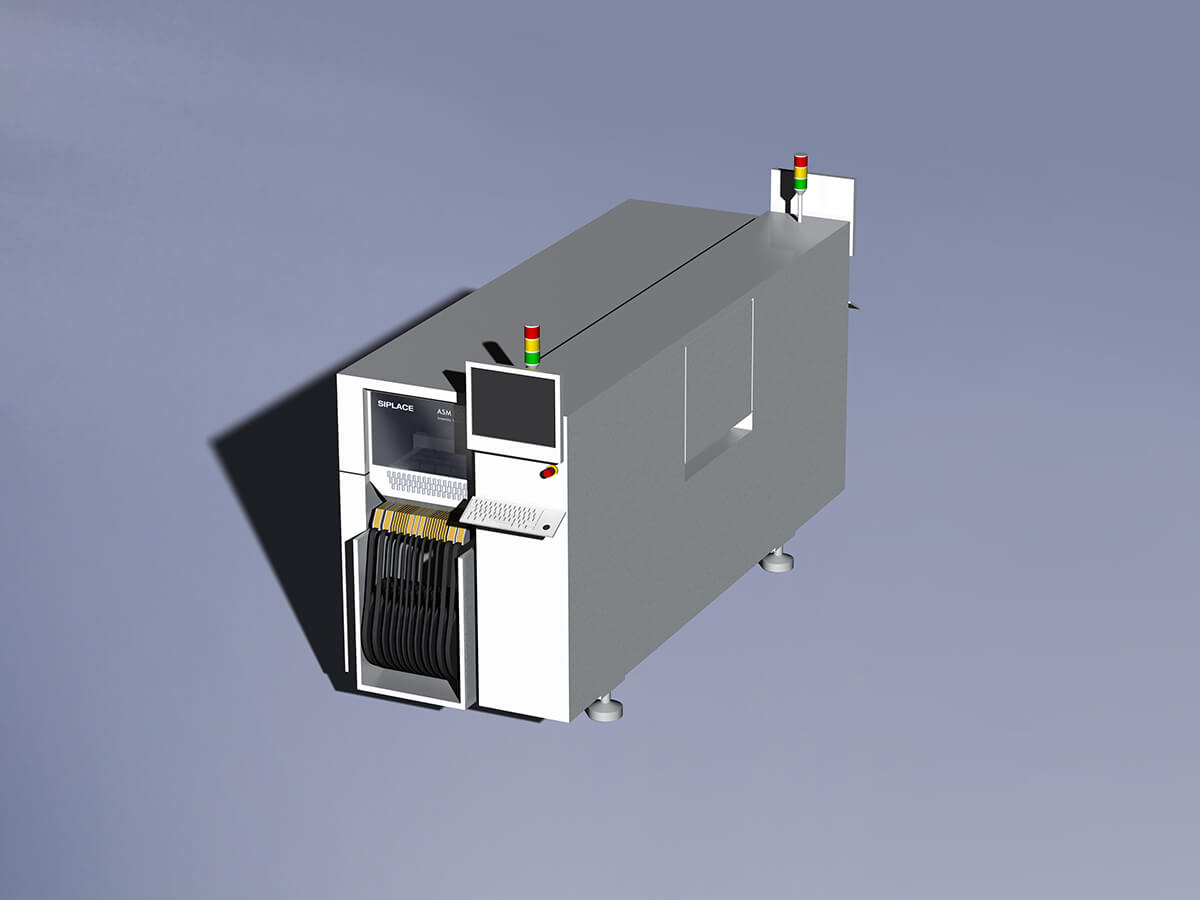

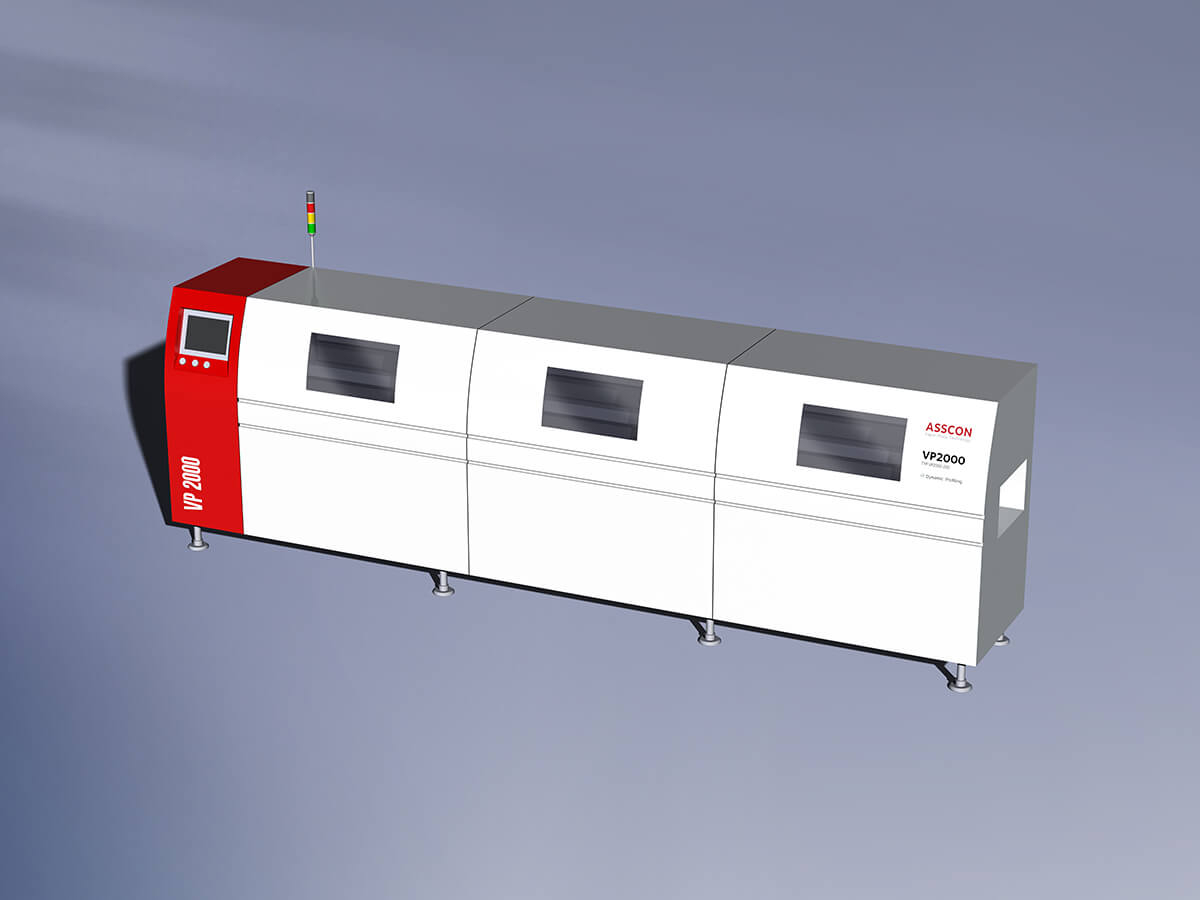

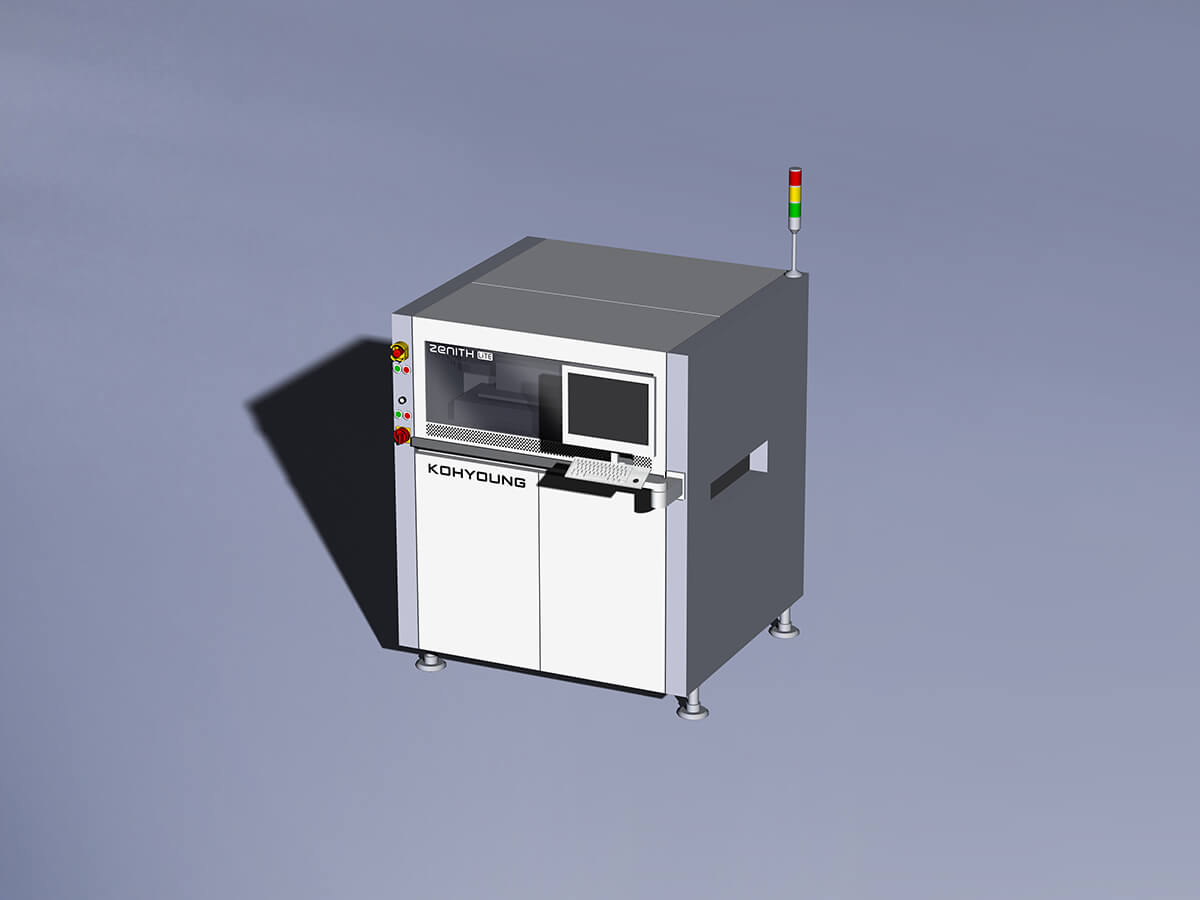

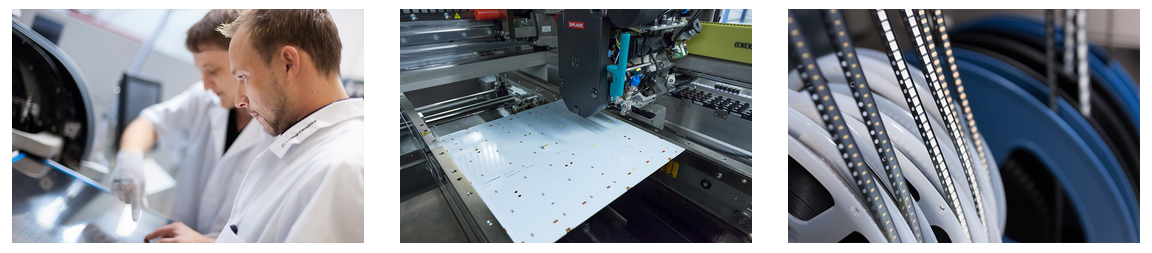

Our development engineers design modules and control technology according to your requirements and matched to your applications such as luminaries, inspection machines, status displays, light modules for domestic appliances and many more. In our in-house assembly line, high performance automatic placement machines by Siemens place large and small components in an extremely fast and precise way. The vapour phase soldering machine by the market leader Asscon differs from ordinary convection soldering furnaces by its extraordinarily gentle soldering process under protection gas atmosphere. This prevents oxidation and cold solder joints and improves the thermal connection of component and PCB. This is particularly advantageous for light emitting diodes, whose aging scales with the operating temperature.

The complete production process can be customised to your requirements and is to a large extent automatised. Production lots can be tracked back. accurately to the Bin. This is of particular importance for industrial applications that continually require the same brightness, colour or voltage for a long period of time. As development, procurement of materials, storage and production all take place on our premises, our process chain is cost efficient, traceable and less prone to failure. No module manufactured by us will leave our house without quality control.

Meeting our quality and safety regulations is our utmost priority! Therefore we produce without any poisonous substances and always work with ESD protective clothes and on ESD surfaces in the production area.

We are a partner you can rely on. Our production facility is certified for quality management in accordance with DIN EN ISO 9001. From respect for the environment it is also certified in environmental management in accordance with DIN EN ISO 14001. Furthermore, we commit ourselves not to use any component or substances hazardous to health or the environment in our products.

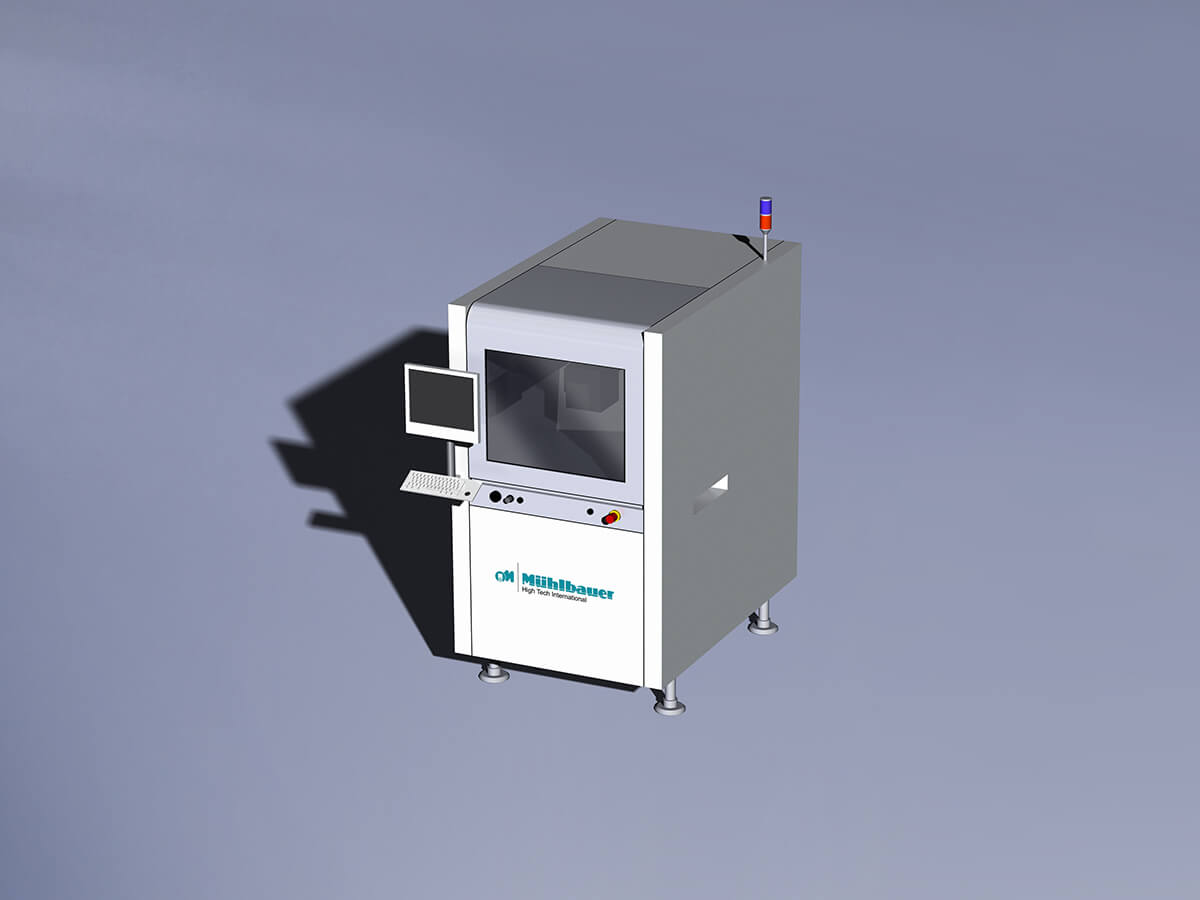

Meet the SMT production line for rigid modules.

Unequalled state-of-the-art production

Our ISO-certified production line has been tailored specifically to the requirements of assemblies with LED technology. Nearly one million components can be processed per day in the production line.

The entire process is flexibly adaptable to the requirements and batch sizes of our customers and runs fully automatically.

- State-of-the-art machinery with the latest technology

- Production of circuit boards with lengths of up to 600 mm

- Traceability thanks to laser bar codes

- Maximum process safety with fully automated processing

- ISO certification

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA