Understading Luminous Efficacy (lumens per watt) and Its Impact on LED Performance

- By Lumistrips LED Professional

- Apr 12, 2023

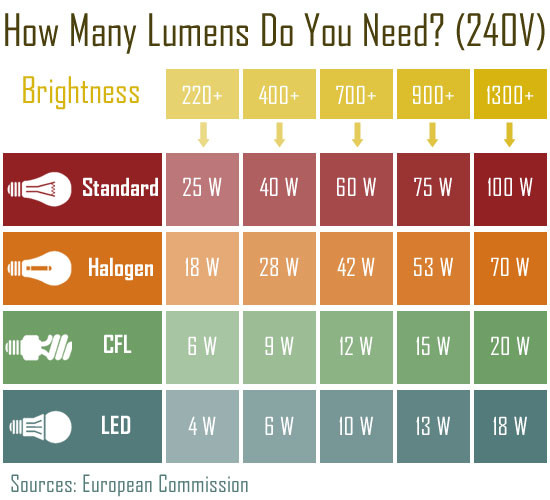

Luminous efficacy measures how effective a light source produces visible light. For LEDs, it is the ratio of luminous flux to electric power.

The highest luminous efficacy today is 220 lumen/watt from the Nichia 757G LEDs with many other manufacturers offering LEDs in the 120-180 lumens per watt range. Low cost LEDs have an efficacy as low as 50 lumens per watt.

| Top performance LED | High Performance LED | Good Performance LED | Low Performance LED |

| 220 lm/W | 150-200 lm/W | 100-149 lm/W | 50-99 lm/W |

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA