LumProtect: Revolutionizing the Future of Lighting with Innovative Lamination Technology for IP67 waterproof LEDs

- By Lumistrips LED Professional

- Dec 7, 2023

LumProtect: Revolutionizing the Future of Lighting with Innovative Lamination Technology

In the dynamic world of lighting design and technology, staying ahead of the curve is crucial. Lumistrips, a leading supplier in LED lighting solutions, has introduced a groundbreaking technology called LumProtect®, which is set to redefine how we think about lighting protection and flexibility. This article explores the many facets of LumProtect, shedding light on its unique features and potential applications in various industries.

The Essence of LumProtect

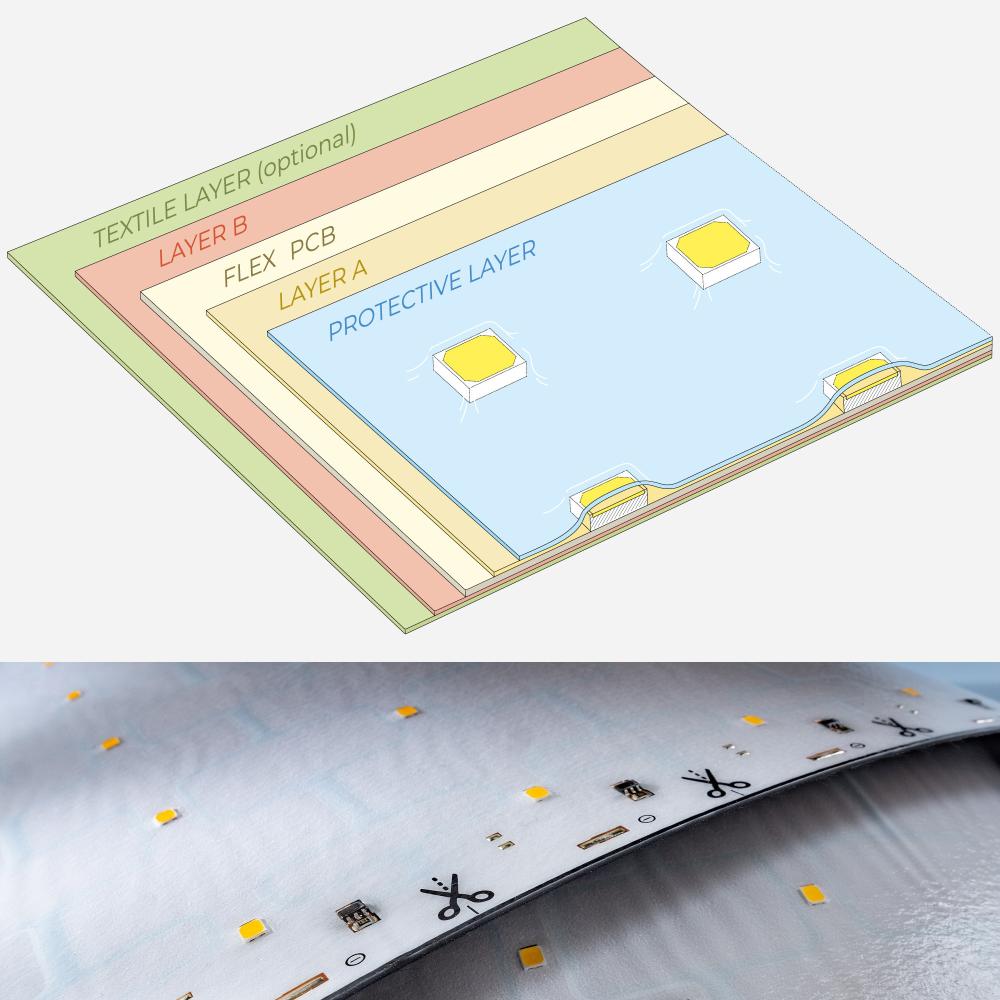

LumProtect is an innovative lamination technology developed by Lumistrips, primarily designed to enhance the durability and versatility of LED lighting solutions. This technology involves the application of multiple thin polymer layers onto electronic assemblies, utilizing a combination of heat and high pressure. The result is a product that maintains the flexibility of LED modules while significantly increasing their mechanical strength.

Key Features and Benefits

- Enhanced Durability: LumProtect's lamination process encapsulates the components, protecting them against environmental factors like humidity, UV rays, and various chemicals.

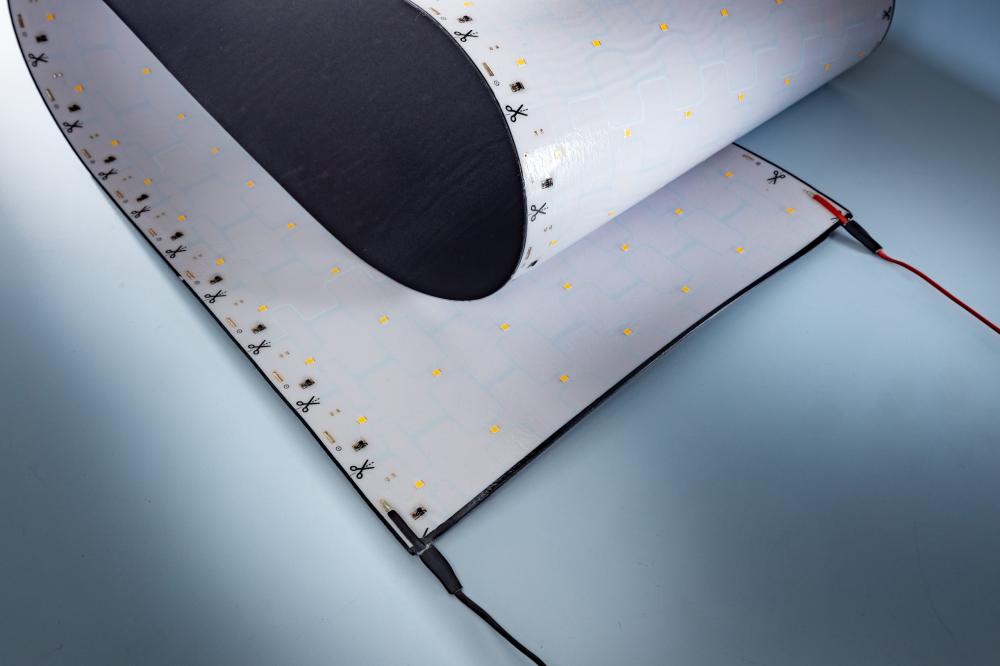

- Flexibility and Versatility: Despite the protective layering, LumProtect maintains the inherent flexibility of the LED modules, enabling multi-dimensional installations.

- Optical Excellence: The technology ensures high transparency (92-94%) and minimal color shifts, making it ideal for LED and sensor applications.

- Environmental Resistance: With an IP67 protection rating, LumProtect modules are built to withstand extreme conditions, including dry heat and salt spray tests.

- Customization Options: The lamination process allows for a range of customization in design, color, and texture, catering to specific aesthetic and functional requirements.

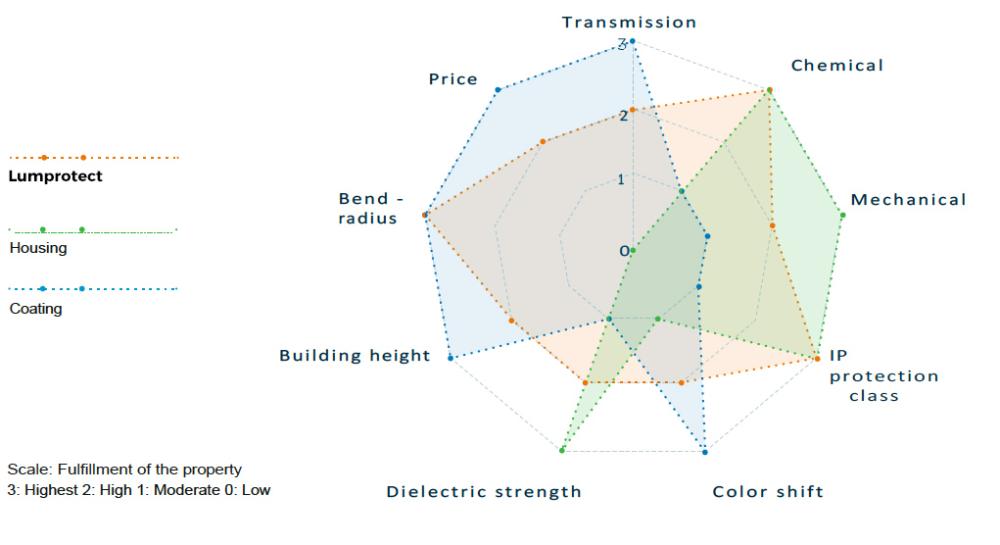

L U M P R O T E C T ® IN COMPARISON

In addition to LumProtect® , there are the two common methods used to protect flexible LED strips electronics: Housing an Coating. However, both of these methods have significant drawbacks. With Coating high protection rating cannot be obtained and with Housing flexibility of the waterproof LED strip is low.

Only with LumProtect® LED modules and strips remain very flexible even when protected with IP67, so that three-dimensional installations can be implemented without restrictions. As only very thin layers are fused together in the LumProtect® lamination process, the flexibility of the LED module is retained. At the same time, the mechanical resistance increases significantly.

Applications in Lighting Design

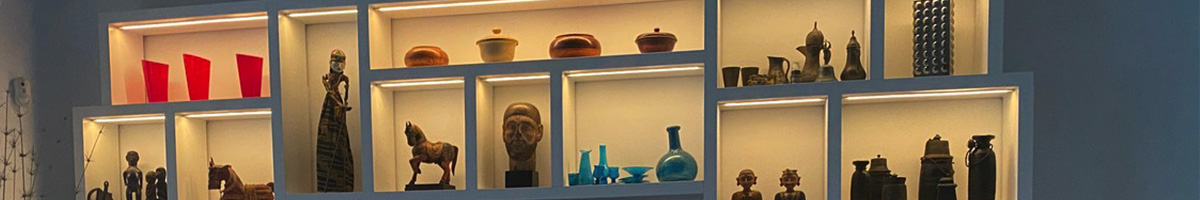

LumProtect's versatility opens up a realm of possibilities in lighting design. From outdoor flexible lighting solutions that can endure harsh weather conditions to sophisticated indoor lighting systems, this technology is adaptable to a myriad of settings. LumProtect is the only waterproofing method that is suitabile for both LED strips and flexible, large area surface modules, making it a game-changer in both residential and commercial spaces.

Case Studies: LumProtect in Action

1. Flexible Electronics: The technology is ideal for applications where flexibility and durability are paramount, such as in wearable technology or curved architectural features.

2. LED Wallpapers: Lumistrips has ingeniously integrated LED technology into wallpapers, offering a unique and aesthetic lighting solution for homes and commercial spaces.

The Technology Behind LumProtect

At the core of LumProtect is a state-of-the-art lamination process. This process involves applying several layers of plastic under heat (<230°C) and high pressure to the front and back of flexible PCB materials. The total layer thickness ranges from 200 μm to 1000 μm. The process ensures air residues are displaced, enhancing the material's composite and flexibility, while significantly boosting mechanical resistance.

Technical Specifications

- Mechanical Parameters: Includes a minimum bending radius and a hardness of 70 Shore D (ISO 868)

- Optical Parameters: No yellowing effects and minimal color shifts, ensuring high color fidelity.

- Environmental Influences: Meets rigorous standards, including dry heat and temperature-humidity cycles.

- High dielectric strength: > 80 kV / mm, 4-5 KV at 50 μm

- High material transparency: 92 - 94 % typical

- Hardly any color shifts: < 200 K for warm white LED light)

Environmental protection:

- IP67 protection = standard

- Dry heat (DIN 60068-2-2)

- Temperature and humidity cycles (DIN 60068-2-38)

- Salt spray test (DIN EN 60068-2-11: 2000-02)

Special features:

- Structured and smooth surfaces

- Customized designs, shapes and colors through the use of textile layers

- Various connection and sealing options with cables, plugs, eyelets & crimp contacts

- Applicable to the entire Lumistrips standard portfolio with LED strips and customer- specific solutions on flexible substrates

LumProtect and Sustainability

In line with global trends focusing on environmental impact and sustainability, LumProtect stands out as a technology that not only enhances product lifespan but also reduces the need for frequent replacements, thereby contributing to waste reduction.

LumProtect by Lumistrips represents a significant leap forward in lighting technology. Its innovative approach to lamination not only protects LED modules but also preserves their flexibility and aesthetic appeal. As we continue to explore the boundaries of what is possible in lighting design, technologies like LumProtect pave the way for a brighter, more resilient, and more versatile future in lighting solutions.

LumProtect IP67 Lumiflex3080 Seoul LED strips, CRI80

LumProtect IP67 Lumiflex2080 Samsung LED strips, CRI80

LumProtect IP67 Lumiflex1080 Seoul LED strips, CRI80

LumProtect IP67 Sample for testing

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA