Designing Efficient Horticulture Lighting Systems for Indoor Agriculture

- By Lumistrips LED Professional

- Feb 28, 2023

As the global population continues to grow, the demand for food increases, and issues such as diminishing agricultural land, pollution, global warming, and migration arise. Industrial-scale indoor agriculture under artificial lighting in closed and fully controlled environments has the potential to become the main factor that prevents famine and related conflicts. To grow plants in a reliable, predictable, and efficient way, it is crucial to understand and correctly apply the concepts of lighting for plant growth and development. In this article, we'll delve deeper into horticulture lighting, its related concepts, and how to design efficient LED lighting systems for indoor agriculture.

Horticulture Lighting Concepts

A successful indoor plant growth environment depends on the efficiency of the lighting system compared to sunlight during the process of plant growth. Photosynthesis, the process by which plants convert light into the chemical energy needed for growth and development, requires photosynthetically active radiation (PAR), carbon dioxide (CO2), nutrients, and water.

Photosynthesis and PAR radiation

The electromagnetic radiation required for Photosynthesis is defined as photosynthetically active radiation (PAR), with 400 to 700 nanometers the spectral range. Only radiation in this interval can be used by photosynthetic organisms in the process of photosynthesis, to fix the carbon in CO2 into carbohydrates.

Electromagnetic radiation called visible light or simply light, for a typical human eye has a spectral range from about 380 to 740 nanometers.

A common unit of measurement for Photosynthetically active radiation PAR is the photosynthetic photon flux (PPF in short), measured in units of moles per second. For many practical applications this unit is extended to PPFD, units of moles per second per square meter.

The theory behind PPF is that for every absorbed photon, regardless of its wavelength and energy, an equal contribution to the photosynthetic process is made. As in accordance with the Stark-Einstein law, every photon (or quantum) that is absorbed will excite one electron, regardless of the photon’s energy, between 400 nm and 700 nm.

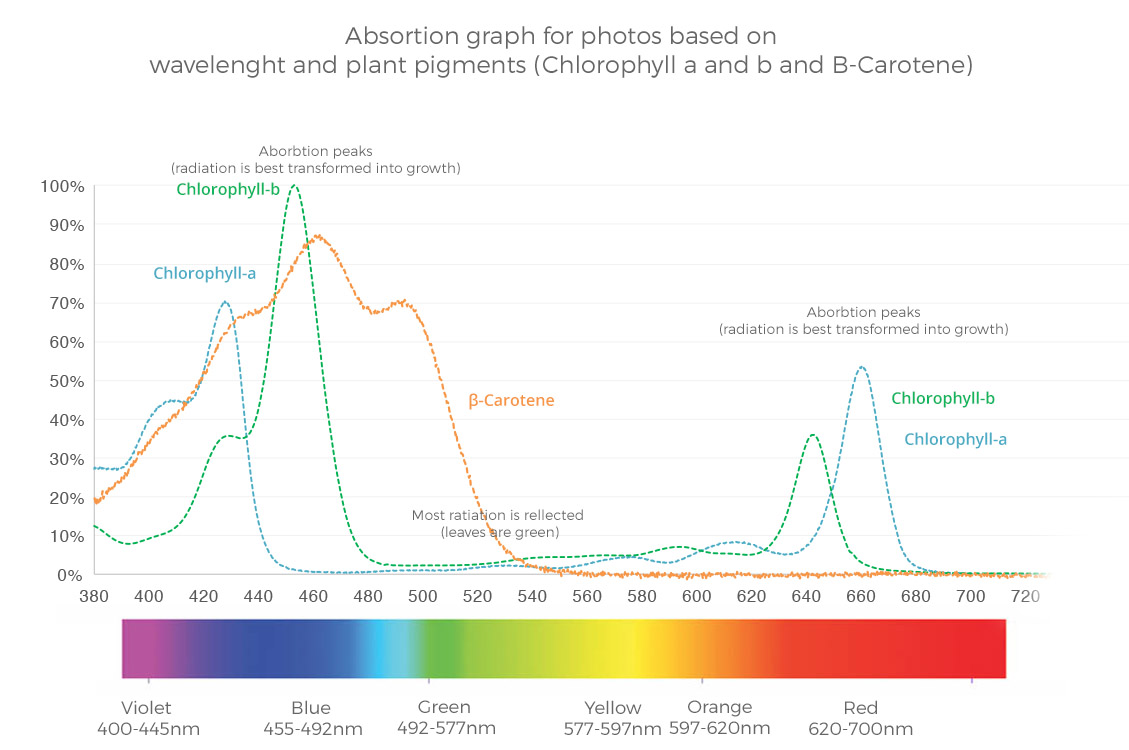

However, only some of photons are absorbed by a plant leaf, as determined by its optical properties and the concentration of plant pigments. The pigments are Chlorophyll A, Chlorophyll B, and Carotenoids (a/-Carotene, Lycopene, Xanthophyll).

The Chlorophylls A and B give plant leaves the characteristic green color because they reflect most of the radiation between 500 and 600 nanometres. Plants with more Carotenoids than Chlorophylls in plant leaves reflect wavelengths beyond 540nm and have yellow, orange, and red colors. This includes autumn leaves when Chlorophylls have dried away.

The graph below shows the typical absorptance spectra for Chlorophyll A, Chlorophyll B and Chlorophyll (beta-carotene). Each are explained briefly afterwards:

Chlorophyll-A (Absorption peaks at 430nm and 662nm)

Chlorophyll-a is the primary pigment for photosynthesis in plants and it exhibits a grass-green visual color. Can be found in all photosynthetic organisms except photosynthetic bacteria.

Chlorophyll-B (Absorption peaks at 453nm and 642nm)

Cholorphyll-B exhibits a blue-green visual color and it occurs in all plants, green algae and some prokaryotes. There is usually about half as much Cholorphyll-B as Cholorphyll-A in plants.

Carotenoids (a/-Carotene, Lycopene, Xanthophyll) (Absorption is strong between 420nm and 485nm)

Carotenes are strongly colored red-orange pigments abundant in plants, fruits, vegetables, and whole grains.

Converting Luminous Flux into PAR radiation (PPF and PPFD)

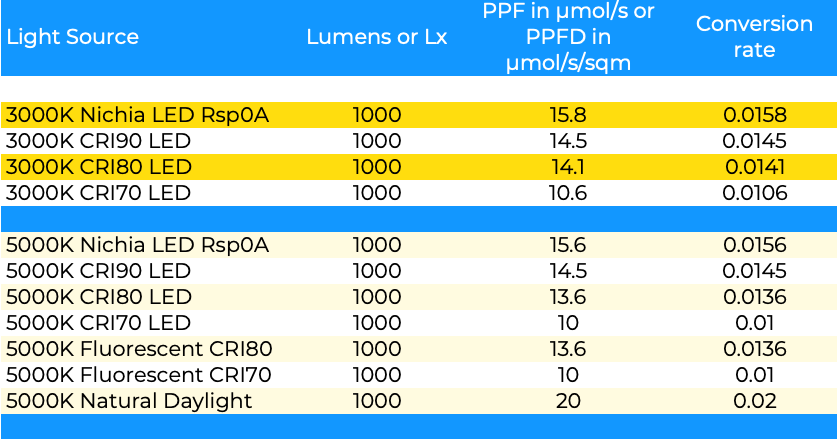

By knowing the absorption peaks of the Chlorophyll and Carotene pigments for photosynthesis, the photosynthetically active radiation PAR (PPF and PPFD) of a light source can be calculated.

Luminous flux, in lumens, is converted in PPF (photosynthetic photon flux or quantum flux) with a mathematical formula based on the spectral power distribution (SPD) of the light source. The result will be a value in μmol/sec that is only relevant to the SPD used in the calculation.

As this conversion requires detailed data of the light source SPD at every 5 nm in tabular format (excel table), it is most often that manufacturers write PPF values directly in the datasheet. Below are some examples of Lumen to PPF conversion:

If the PPF value is not mentioned for a light source, the above numbers can be used for a conversion, but with approximate results only. An alternative method of evaluating how effective is the lighting for horticulture would be to superimpose the spectral power distribution (SPD) graph that is available in datasheets on the absorption graph.

While PPF (photosynthetic photon flux) is the total energy emitted from the light source, the energy actually received by plants is th photosynthetic photon flux density (PPFD) and its S. I. units are µmol/sec/m2.

Iluminance, in lux, can be converted into photosynthetic photon flux density (PPFD) in a similar way but with one important difference.

It is a value influenced by the distance and optical properties of the light source (view angle) and is more often measured on the site of installation, not found in the manufacturer datasheet. This approach is difficult when the lighting installation is in the planing stange as it requires the LED fixtures to be already in place.

The below conversiont tables can help with desiging of the horticulture lighting installation.

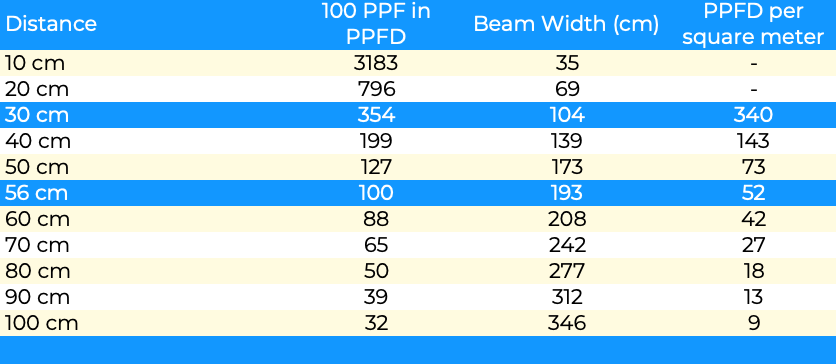

1) Convert PPF in PPFD.

The table below shows a PPF to PPFD (100 PPF to PPFD) conversion for a LED lightsource (LED strip) with 120 degree viewing angle. It is important to note that the PPFD per square meter is valid for one square meter of growth area. If the are is larger areas, LED modules, placed at each square meter, will iluminate the adiacent squares so the value will be higher.

We recommend a distance of 30 cm between the plant leafs and the LED strip/module so the LED will iluminate exactly one square meter of soil.

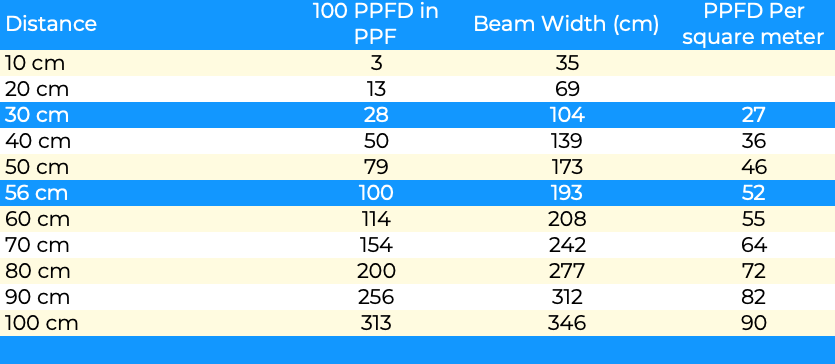

2) Convert PPFD in PPF

Usually recommeded light levels for plants are expressed in PPFD. For this reason, PPFD conversion to PPF can be more useful.

Once we know the PPF and PPFD values for a light source we can proceed to design the proper light system for growing plants indoor.

Recommended PPFD for common vegetables and decorative plants

The next step to design the horticulture light system is to research the light intensity suitable for photosynthesis for the specific plants you plan to grow.

There are plants that grow naturally in the shade as their leaves require low light intensities and are such referred to as “shade plants”. Other plants grow in the sun with leaves that need high light intensities. They are referred to as “sun plants”.

Most vegetables (watermelons, tomatoes, cucumbers, melons…) are sun plants while many flowers (alyssum, baby blue eyes, begonia, calendula, fuchsia…) are shade plants.

Generally, plants that grow at low light intensities (shade plants) have large, thin leaves while plants that need high light intensities (sun plants) have thick leaves.

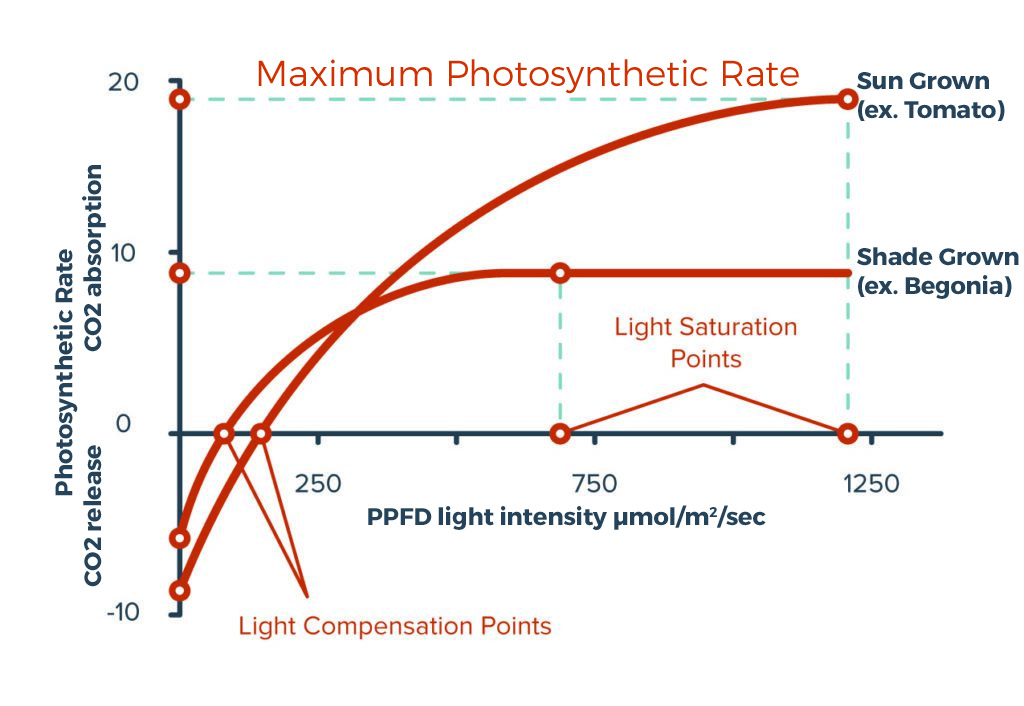

Depending on each plant, photosynthesis is apparently starting at certain light level, named compensation point. As the light intensity increases so does the photosynthesis and plant development, until a particular point that is called “light saturation point". Beyond it, the amount of light striking the leaf does not cause an increase in the rate of photosynthesis, the amount of light is said to be 'saturating' the photosynthetic process.

The compensation point and saturation points are discovered by observing the phenomenon of CO2 absorption and release. As the light intensity drops below the compensation point, a CO2 release is observed, as it increases above it CO2absorption gradually increases until the point of saturation where if flattens out at the maximum level.

A suitable light intensity for a horticulture installation is recommeded to be in the compensation - saturation interval for the plants that are grown.

Below there are examples of compensation, saturation and recommended values for vegetables and crops (Letuce, Tomatoes, Cannabis, Red peper, Cucumber...)

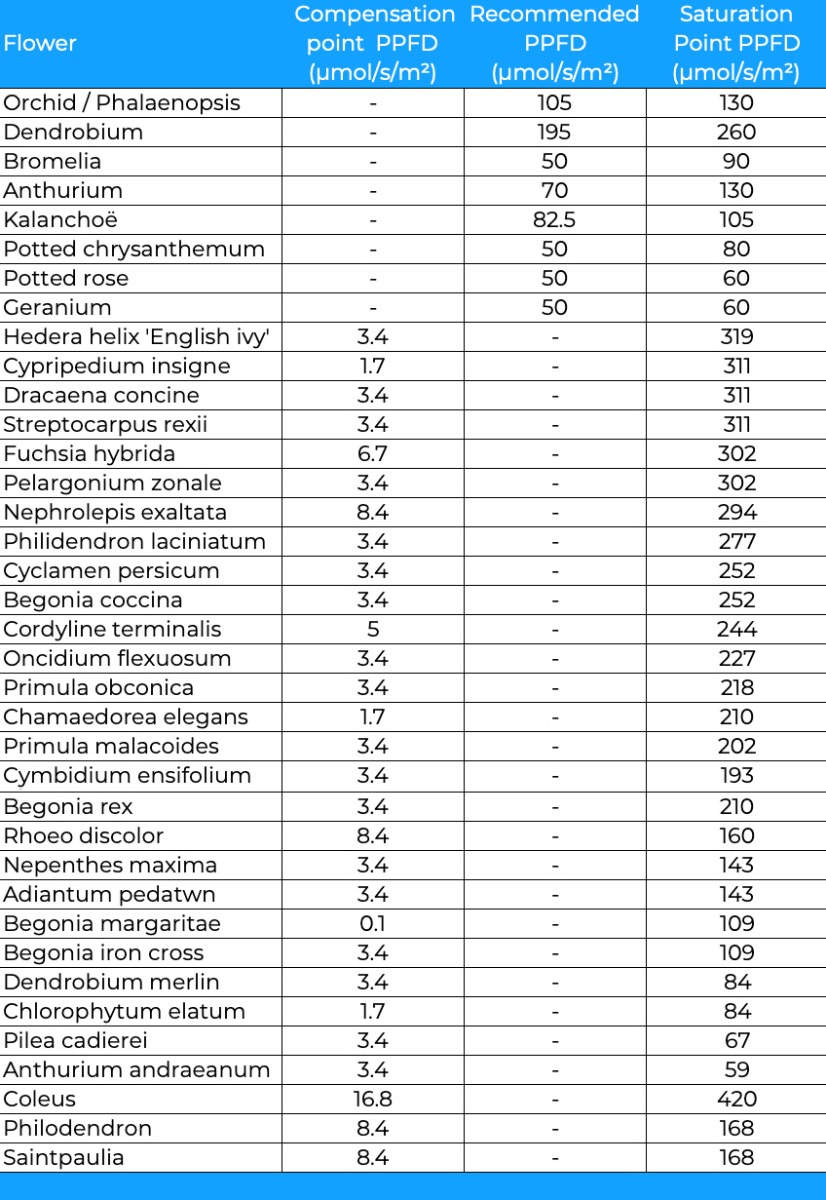

Below are compensation, saturation and recommended values for decorative plants.

Designing the most efficient Horticulture LED lighting system

For example, a typical lighting installation for cultivation facilities utilized for salad and lettuce would have a typical light intensity of about 300 to 400 µmol/m2/sec. Locations where a higher light intensity is needed, such are hybrid type factories, a supplemental lighting of 100 to 150 µmol/m2/sec is required.

Currently LED lighting provides the most efficient and cost effective way to illuminate cultivation facilities. However not all LED lighting systems are created equal.

Below are the very important attributes that make the difference.

1. Efficacy: PPF/Watt

The LED system should have a very good PPF per power consumption ratio (PPF). For example, our LumiBar3098+ LED strip at 5000K has 1.82 PPF/Watt, one of the highest on the market.

2. Color stability

The LED system should have a minimum color shift over its lifetime of operation otherwise its effectives at growing plants will be severely affected.

As a general rule, long lifetime LEDs, such as those manufactured by Nichia, Osram or Cree has excellent color stability.

3. Color sorting

White LEDs, as with all manufactured products, have material and process variations that yield products with corresponding variation in the shade of white light emitted. For example Nichia warm white LEDs just out of the production line can have a color temperature between 2580K and 4260K. If they would be directly integrated into strips or luminaries for plat growth the results will be inconsistent.

To prevent the issue above LEDs must be sorted and grouped in batches known as "Chromaticity Bins". Thus it is possible to have all the LEDs in strip or luminaire have the same color temperature from the visible point of view. For this to happen a 3-step MacAdam Ellipse sorting is needed.

4. Easy installation or replacement of modules

Horticulture makes intensive use of the lighting system, with typical 12-16 hours daily run time. For this reason the modules or strips should be easily replaceable.

With advancements in technology, special or full-spectrum white light LEDs have emerged as the most efficient and cost-effective light sources for plant growth. Our full-spectrum/Rsp0a CRI98+ LED strips will help your plants grow up to 50% more than conventional light sources, such as standard white LEDs, a combination of red and blue LEDs, or fluorescent tubes, while consuming less energy.

We recommend:

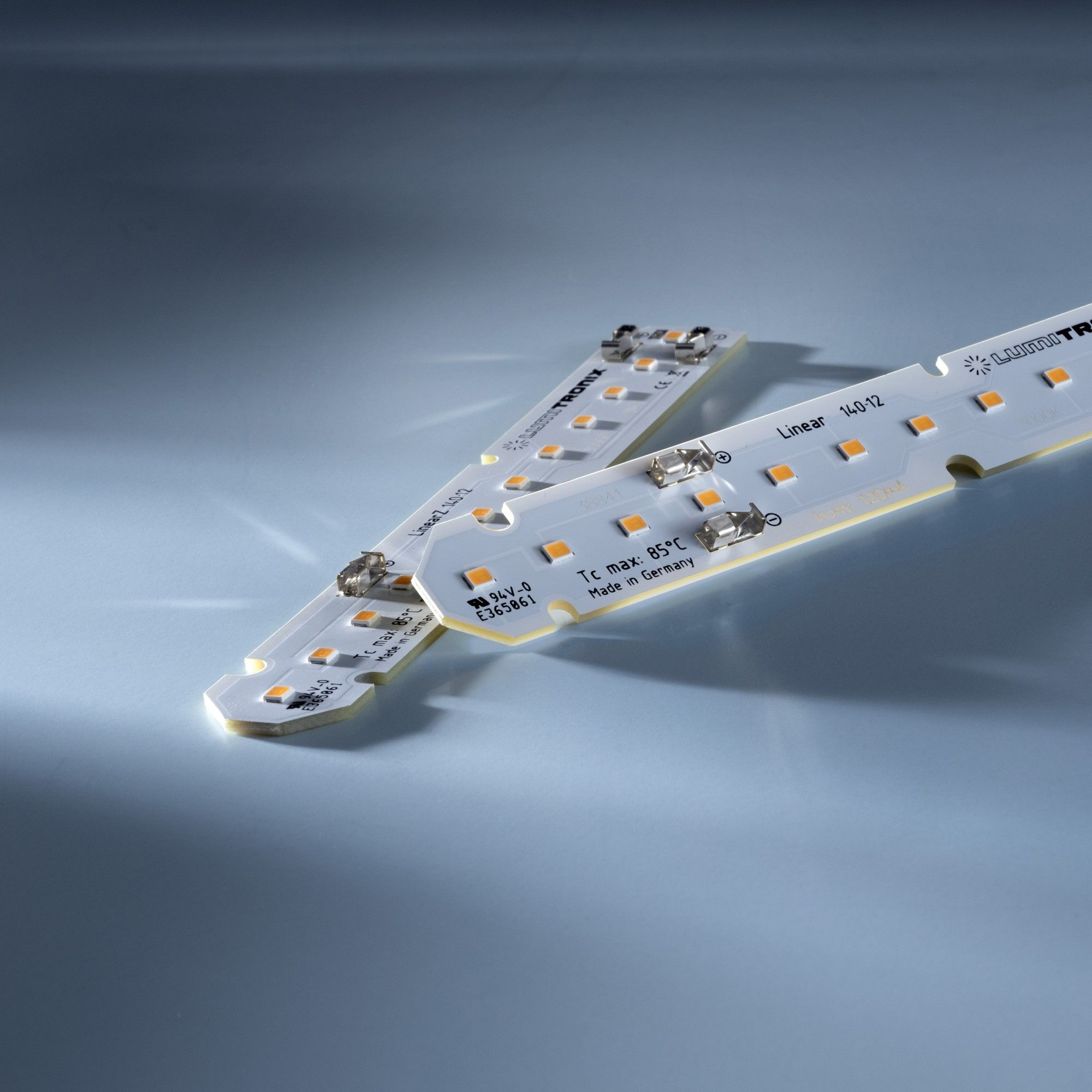

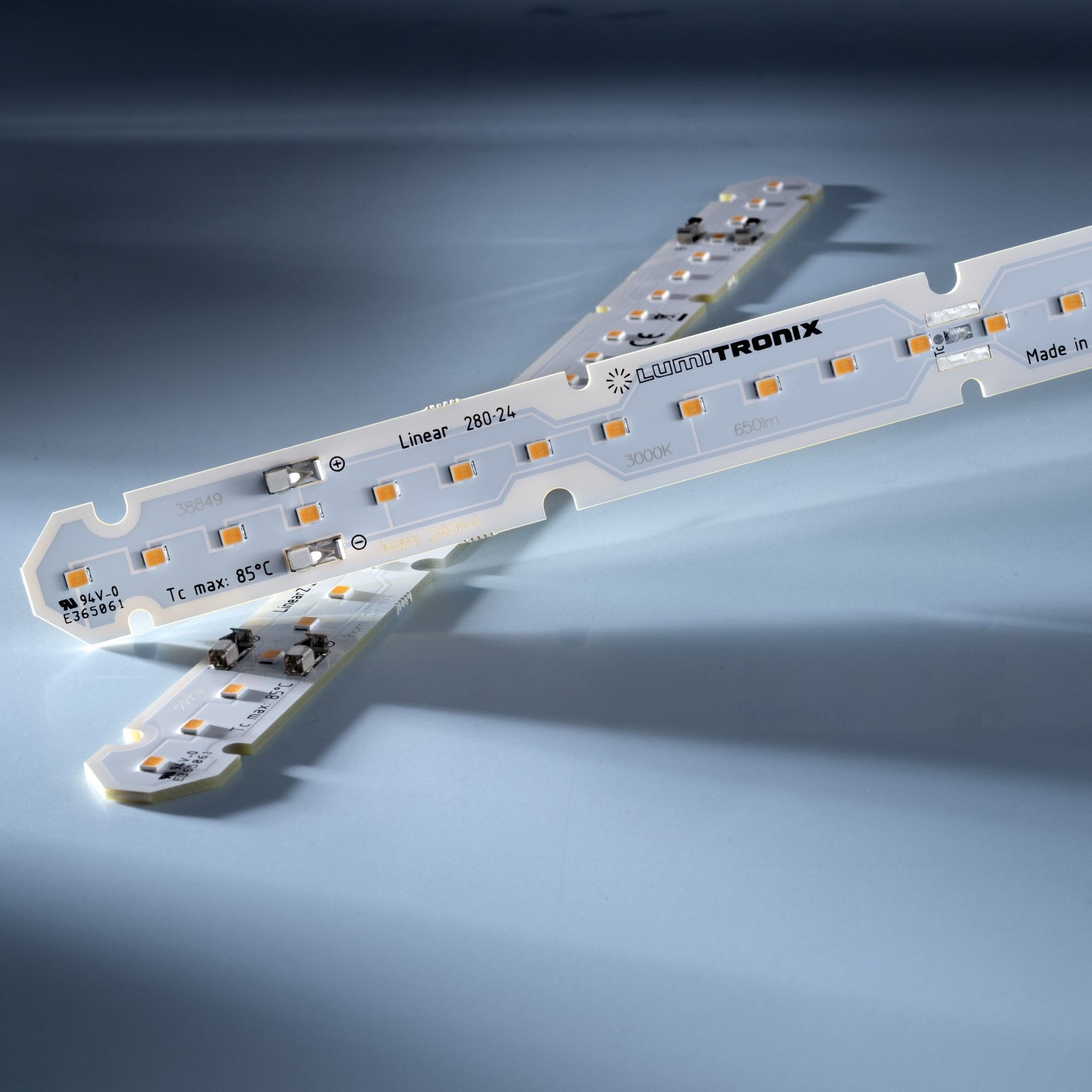

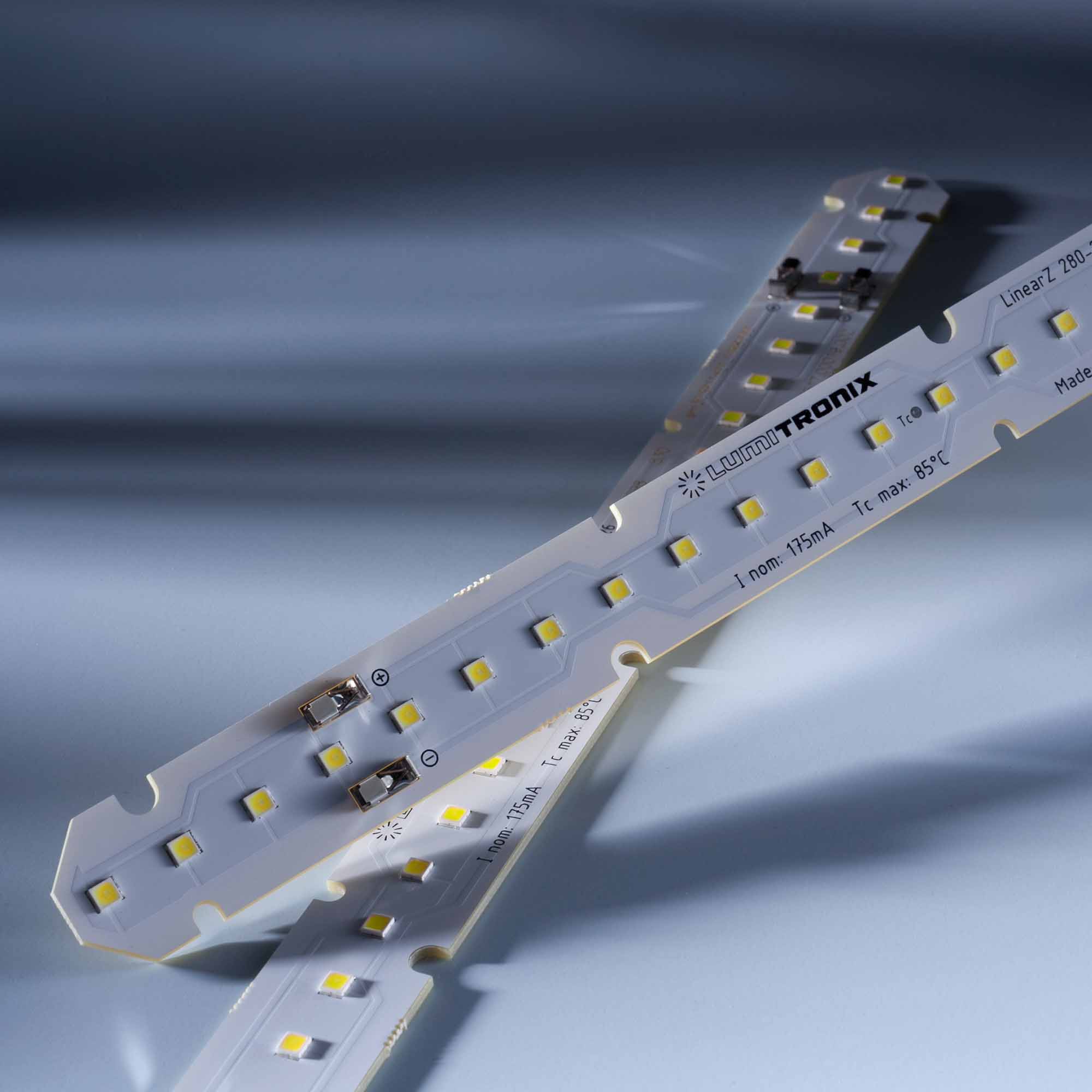

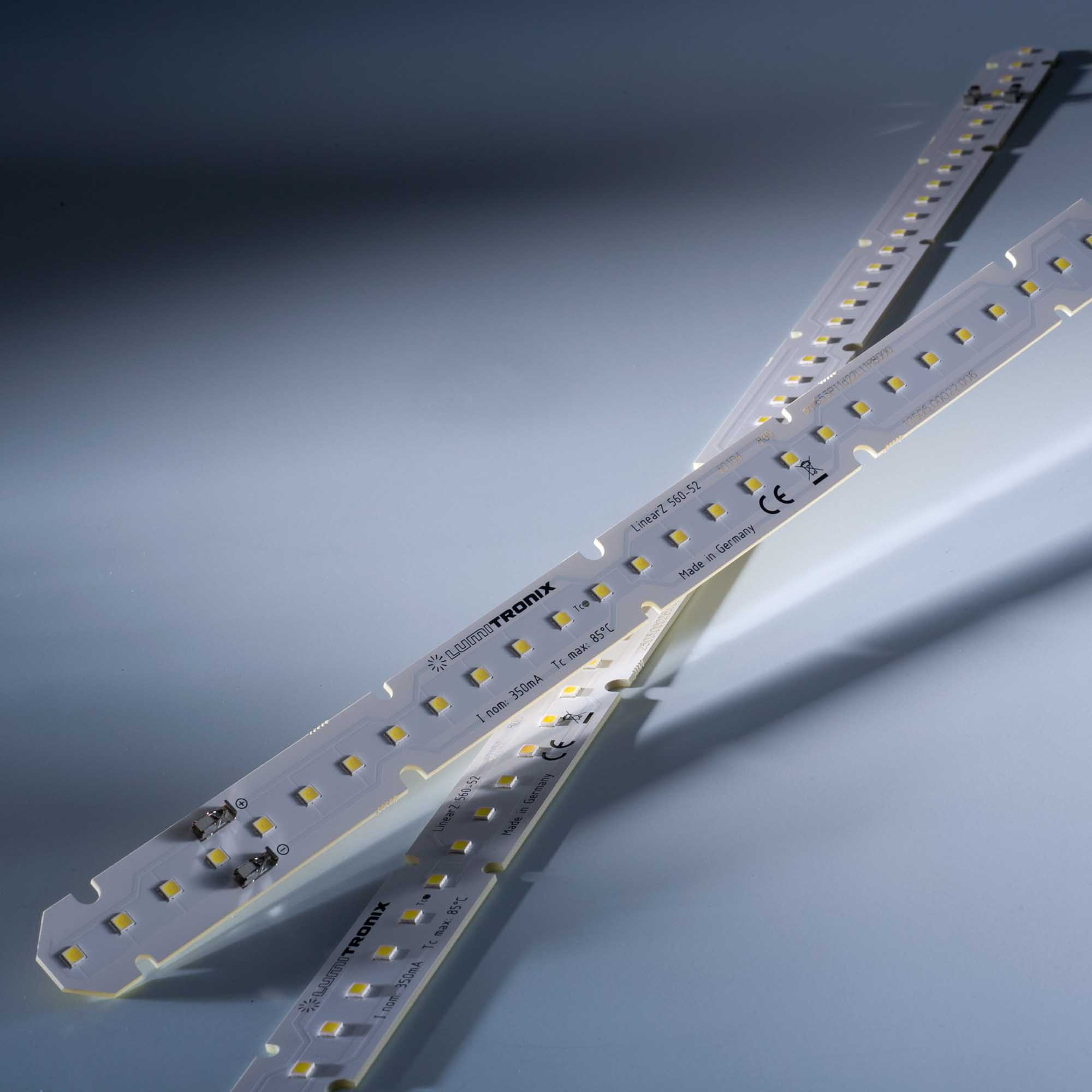

Our LumiBar LEDs with CRI98+ are available in easy-to-install plug & play modules that adhere to the Zhaga Standard. LumiBar modules feature a Plug & Play power system that enables wire connections without the need for a soldering gun, and they are available in a constant current version for maximum energy efficiency.

For dimming and light control via Casambi, the recommended drivers and control button are:

If you're looking for a more flexible option, consider our LumiFlex3098+ 24VDC Flexible LED strip, which is also easy to install and control.

For dimming and light control via Casambi, the recommended drivers and control system are:

As the need for industrial-scale indoor agriculture continues to grow, understanding and implementing efficient horticulture lighting systems becomes increasingly crucial. By considering factors such as plant pigments, PAR radiation, and LED system attributes, you can design an effective and energy-efficient lighting system to support the growth and development of various plants. This will not only contribute to addressing the challenges of increasing food demand but also promote sustainable agriculture practices and help prevent famine and related conflicts.

By following these guidelines and using the right products, you'll be well on your way to creating a highly efficient, cost-effective lighting system that promotes optimal plant growth in your controlled environment.

Lumistrips UK

Lumistrips UK Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA